Case Study Case Study

Rail track/structure interaction

analysis for the Honam high speed railway

-

Rail track /

structure interaction analysis

-

Temperature,

acceleration and braking loads evaluated

-

Induced rail

stresses and track displacements all within design limits

Saman Engineering

Corporation is using LUSAS Bridge analysis software for

preliminary design work on the Honam high speed railway on behalf of

its client the Korea Rail Network Authority. As part of this work, a

rail track/structure interaction analysis has been carried out for a

1.8km long viaduct bridge structure, with a 3-span centre section of

steel box framed construction, that carries the railway over the

Mangyeong River near Iksan. Axial forces in the rails due to

acceleration and braking forces caused by passing trains were

evaluated and induced track displacements relative to the bridge deck

were checked and found to be within the specified design limits.

Overview

The Honam high speed railway, when

complete, will link South Korea’s capital city, Seoul, with Mokpo, a

southern port city in South Jeolla Province. It will be South Korea’s

second high speed railway. The first, the Seoul-Busan line, has been

in operation since 2002. The Mangyeong River crossing, one of many

structures on the new route, has a length of 1,875m and comprises a total

of 50 spans of varying length and construction type. Three steel box

framed spans of 60/75/60 metres over the river are flanked by steel

girders of 50m span, and then by various numbers of 35m and 30m

pre-stressed concrete box section spans for the remainder of the

crossing’s length.

Rail Track Analysis

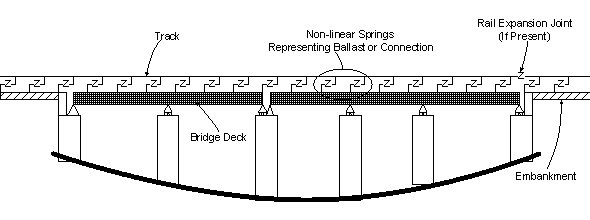

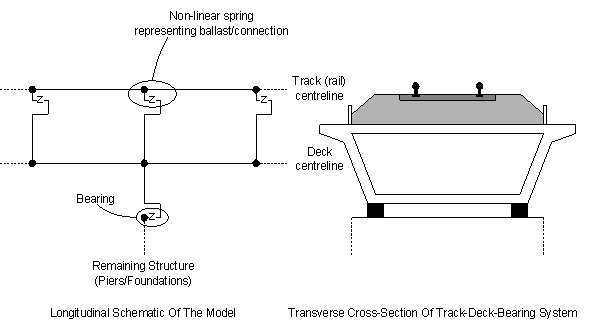

To model the bridge Saman used the

LUSAS Rail Track Analysis option. This allows rail track/bridge

interaction analysis to be carried out to the International Union of

Railways Code UIC 774-3. It builds models automatically from data

defined in MS Excel spreadsheets, runs an analysis, and produces

results in spreadsheet or LUSAS formats. To do this, the bridge is

simplified and ‘broken-down’ into beam elements which represent

the track and any supporting structure, with nonlinear springs being

used to model the ballast and expansion joints. Bearings and

foundations are modelled

with simple springs. Temperature change in the rails and structure,

and train loadings from acceleration and braking forces must also be

defined. Changes in temperature and the passage of trains on different

tracks accelerating or braking across the structure induce axial

compressive forces in the rails and displacements in the rails

relative to the bridge deck. These needed to be evaluated to ensure

that they remain below specified design values for all in-service

situations.

The UIC 773-3

Structural System

UIC 773-3

Track/Deck Modelling

Typical train loading

configuration

Typical train loading

configuration reversed

Modelling and

Analysis

For the Mangyeong River crossing,

Saman created two LUSAS models to investigate the response of the

structure. In one, automatically generated by the rail track analysis

option, single beam elements modelled the deck and all spans of the

structure. In the other, the initial rail track analysis-generated

beam model was additionally edited in LUSAS to include the 3-span

framed steel box members and included appropriate geometric and

material properties for the added features. This somewhat unique

method of increasing the accuracy of the UIC code analysis

subsequently proved to be of real benefit when the results from both

modelling methods were compared.

Results

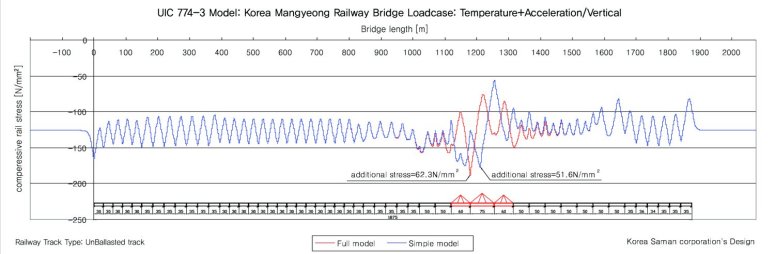

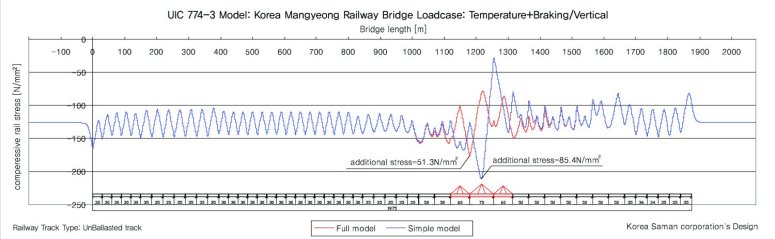

From the results obtained from the

LUSAS rail track analysis Saman created graphs for both the simple

model (using beams only) and the full model (which additionally

modelled the framed steel members). These showed the variation of

axial compressive stress in the rails as a result of the temperature

and acceleration / braking loading. From these graphs it was seen that

full modelling of the steel framed members produced a reduced axial

compressive stress in the track over that shown for the simple beam

only model - reassuring Saman in its design.

Mr Jeongil Kim, Assistant Senior

Engineer in Saman Engineering's Railway Structures Department said: "Correct modelling of the nonlinear behavior of ballast,

and of the interaction between the ballast and the rail track is not

easy to do manually, so the LUSAS Rail Track analysis option, which

handles this automatically, was very useful to us in this

respect". He continues: "The easy use of the rail

track analysis option was a key benefit on this project. Even though the

model was built automatically we could still modify it for our own use

without it ruining the original model".

Compressive

stress in the rails from temperature and acceleration loading for

both simple (beam only) and full (including framed steel members)

models

(click for larger image)

Compressive stress in

the rails from temperature and braking loading for

both simple (beam only) and full (including framed steel members)

models

(click for larger image)

"Correct modelling of the

nonlinear behaviour of ballast, and of the interaction between the

ballast and the rail track is not easy to do manually, so the LUSAS

Rail Track analysis option, which handles this automatically, was very

useful to us in this respect".

Mr Jeongil

Kim, Engineering Manager, Saman Engineering

Find out more

Other LUSAS Bridge case studies:

|