Case Study

The Olympic

Cauldron

- Stainless steel gas burning structure

- 3D static, dynamic and buckling analysis

- Calculation of structural displacements for critical service

connections

Tierney & Partners, one of

the leading Australian Civil & Structural Engineering Consultancies

was responsible

for the structural design of the Olympic Cauldron, mast and transport components

used at

the opening ceremony of the Sydney 2000 Olympic Games. LUSAS Civil & Structural

analysis was used to assist with the development of this prestigious project.

Overview

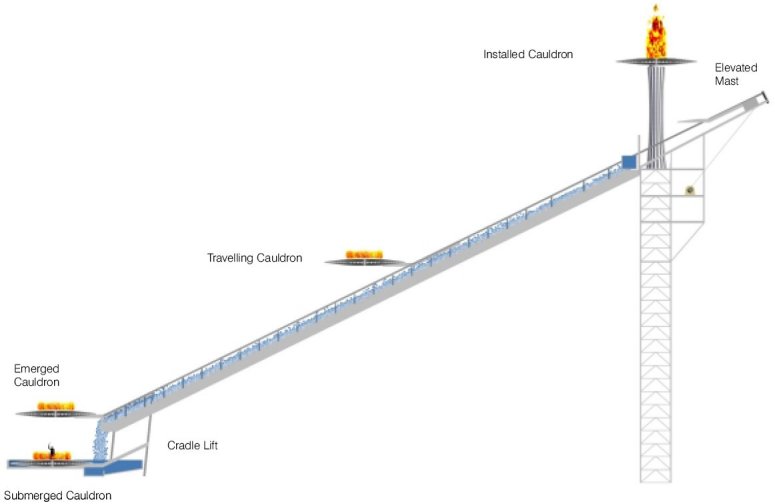

The 8.5 tonne cauldron was designed

to be a perforated, corrugated shell structure fabricated from

stainless steel. It has an overall diameter of 10m and tapers from

0.85m thick at centre down to 0.15m thick at the edge. During the

opening ceremony it was raised from its submerged resting place

beneath ground level and traveled up an inclined cradle lift to a

point from where it is then lifted up to a final position on a mast

50m above the ground.

The complex structure required an

accurate stiffness assessment to be made. This was critical as the

mechanical components needed to compensate for deflections at

various stages of transport.

Design development

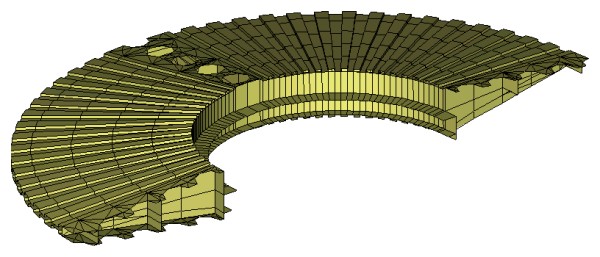

The cauldron was modelled in LUSAS

Civil & Structural using 3D shell elements and 3D static,

dynamic and buckling analysis was carried out to investigate self

weight, wind, and dynamic effects caused during the transporting the

cauldron to its final resting place. LUSAS showed how the cauldron

structure would perform under various transient loading and

supporting conditions, and highlighted a number of elements with

relatively high local stresses. If some elements or connections were

to fail during use it was possible to foresee the re-arrangement of

the load path and overall behaviour. This further increased

confidence in the LUSAS model and hence the structure as a whole.

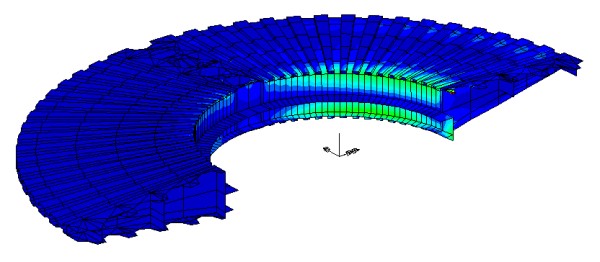

The LUSAS results confirmed

preliminary assumptions that the stiffness of the shell, although

corrugated, plays a major role in the strength and stiffness of the

cauldron structure. Relying on the contribution of the corrugated

and perforated shell, discretely connected to the internal frame,

enabled this frame to be extremely light. Apart from an obvious cost

effect, this proved to be critical as the project was nearing its

completion and the weight of equipment was gradually increased from

an initial 5 tonnes to a final 8.5 tonnes.

| Results obtained were in the expected

range. In fact, first results showed deflections slightly below

initial estimates. However, this "benefit" was soon lost

as more and more gas, electrical and mechanical equipment was added,

increasing the original weight of cauldron by over 60% at the end of

project. Due to presence of the shell the cauldron structure was

able to absorb this increase in load without adversely affecting its

performance. Furthermore, some connections, and in particular those

critical ones near the cradle support for the cantilevering

condition, had to be significantly modified to accommodate

operational requirements (attaching and detaching gas lines and

engaging/disengaging mechanical parts). Time did not allow

re-modelling of the cauldron to test it against proposed changes.

However, as a thorough understanding of the behaviour of the

cauldron components had already been gained, it sufficed to alter

some properties of the relevant components of the model, which

enabled quick and practical modifications to be approved within

hours of the request for change.

|

|

As Zlatko Gashi, engineer on the project says: 'when reliable and

accurate understanding of the behaviour of the structure is required, it can only be

achieved by taking into account all relevant structural components. Neglecting some

components could grossly underestimate the strength and stiffness of the structure.

Complex, sophisticated structures require a modelling and analysis tool such as LUSAS

which can handle all the aspects of structural design, without burdening the designer with

a further complexity of tool itself. In addition, careful planning before the

modelling, and envisaging potential future modifications and critical issues, is a key to

successful design, and ensures that all benefits can be obtained from the model throughout

the design and construction stage of the project."

Legacy

After the Games, The Cauldron was

relocated to Cathy Freeman Park (formerly The Overflow), a few

hundred metres from the Olympic Stadium, where it now stands on 24

stainless steel columns and showers water down on those passing

beneath it. At its base the names of the 1,972 Olympic Medalists and

2,627 Paralympic Medallists at the Sydney Games are recorded on

gold, silver and bronze nameplates.

The Cauldron in its

legacy form as a sculpture/fountain in Cathy Freeman Park.

"Complex, sophisticated structures require a modelling and analysis tool such as LUSAS

which can handle all the aspects of structural design, without burdening the designer with

a further complexity of tool itself."

Zlatko Gashi,

Project Engineer, Tierney and Partners

Find out more

Other LUSAS Civil &

Structural case studies:

|

|

Software Information

|