Case Study

Fatigue

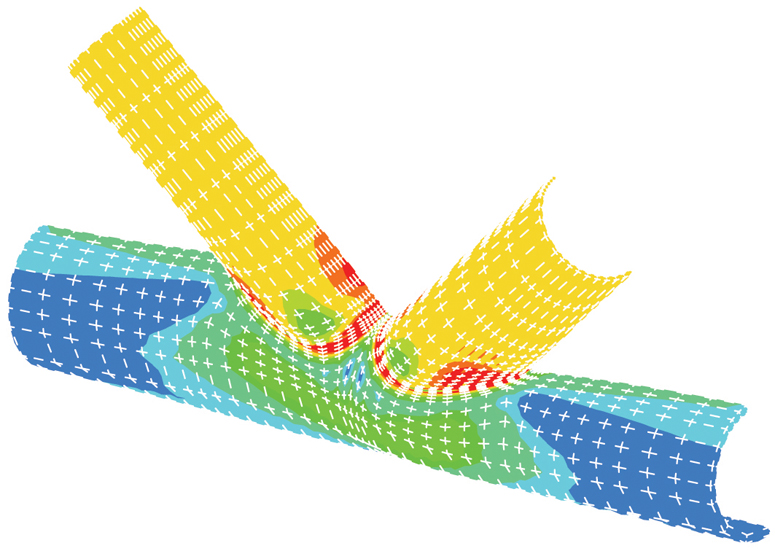

Analysis of Tubular Joints with Single-Sided Welds

MSL Engineering, a leading UK Engineering Consultancy specialising in

advanced analysis, assessment, repair, R&D, audit, verification and reliability

evaluations for the offshore industry used LUSAS to investigate the stress distributions

in typical offshore K joints formed from single-sided welds. K joints are a popular leg

configuration for North Sea structures and consist of two brace members welded to an

existing section (the chord) in a K configuration. It is usually the welds that are of

concern because of their potential for failure by fatigue.

Construction of tubular joints in North Sea Platforms has typically

relied on access to the inside of the brace to either dress or complete a full penetration

weld. However, it has been recognised that welding of tubular joints from the outside

only, represents a cost-effective construction method; this technique results in tubular

joints with single-sided welds. It has also been recognised that single-sided welding

represents the only real option for retrofitting new brace members in existing offshore

installations. Additional bracing may be required in a number of instances, including

replacement of damaged braces or upgrading of the installation to support extra topsides

facilities

With double-sided welds, the weld quality on the inside and outside is

similar and the controlling site for fatigue is typically on the outside because the

combination of notch stresses and stress concentration factor (SCF) here is greater. With

single-sided welds, potential root defects contribute to a lower quality of weld on the

inside. Consequently, unless the SCF on the outside is significantly greater than that on

the inside, potential fatigue problems may originate on the inside where they are far more

difficult to detect. Therefore, the design problem is one of determining the SCF at both

the inside and the outside and determining which site contols fatigue life.

The schedule for this project was tight, so MSL’s engineers for the

project worked with one of FEA’s consulting engineers for a number of days to enable

the FE models to be rapidly created. Initially, MSL used the LUSAS pre and post-processor

to perform the geometric modelling of the braces and chord. This required use of advanced

facilities in LUSAS for modelling the intersection of the cylinders and the weld itself

coupled with manual interaction to establish the final mesh details.

The project was conducted in two stages. The first involved validation

to ensure that the FE strategy, type of element and the mesh density were appropriate to

give accurate results. This encompassed modelling the geometry of one particular

configuration of K joint for which experimental data had previously been obtained using

strain gauges. The validation analysis indicated that using only one layer of the 20-noded

brick elements to model the chord and braces gave sufficient accuracy.

The second stage was to investigate how various geometric parameters of

K joints, such as ratios of brace-to-chord diameter, chord diameter-to-thickness, affect

SCF’s. After careful evaluation of the analysis results obtained from

LUSAS, MSL

observed that a near-linear relationship existed between some of the geometric parameters

and SCF ratios. In the future, the results from these investigations will be used to

assist in fatigue evaluations of offshore structures which contain tubular joints formed

with single-sided welds.

Other LUSAS Analyst case

studies:

|