User Area

Software Release History - Version 16

New Facilities and Improvements

in LUSAS Version 16.0

Release history

V16.0-3 made available on 13 January 2020

This is an error

fix release to correct an urgent software issue preventing the loading

of any results file generated since midnight 1st January 2021 into

LUSAS Modeller.

Other error fixes and

change requests are included.

V16.0-2 made available on 9 April 2018

This release is an

error fix release for various change requests

- Read the Release Note for full

details of all changes made.

Go to

Software Download page

V16.0-1 made available on 14 November 2017.

Version

16.0 of LUSAS is a major software release that sees the introduction

of steel frame design checking capabilities into LUSAS Modeller and a

host of other new features and enhancements to improve general

usability and make collaboration

between design teams easier.

In addition to steel frame design.

other design code-related improvements and enhancements include those

for reinforced concrete slab design, traffic load optimisation, design

load combinations, and response spectra for various design codes. New

worked examples are provided to show how the new design checking and

design load combinations facilities are used.

- Analysis-related improvements

include the ability to define a cable tuning loadcase in a

nonlinear analysis, the introduction of p-delta analysis

capabilities, time-dependent prestress, and eigenvalue buckling of

stressed structures. A time management facility allows for easy

adjustment of the duration of pre-defined construction stages in a

staged construction analysis.

- Of many new results processing

features, inspection locations, which obtain results for

user-defined positions of interest anywhere on a model are of

particular note, along with enhanced averaging of results, and

improvements to graphing, section slicing and combinations. For

printed results, the Print Results Wizard dialog is now used to

add chapters of selected loadcase results to a model report.

- For general modelling, model

analysis categories have been introduced. Selection of an analysis

category simplifies the user interface to generally only show

those menu items and options that are appropriate to the type of

model being defined - all helping to enhance the modelling

experience and adjust the user interface based on the analysis

category. Models can now be merged together allowing two or more

people to create separate models of specific parts of a structure

simultaneously. BIM import / export is now provided. Section

property calculation now supports compound sections, infilled and

encased sections, and thin walled arbitrary sections defined

solely by lines. Perspective viewing has been introduced, and

layout grids and new point, line and surface drawing options

speed-up the creation of frame models. Temperature dependent

material properties can be defined in LUSAS Modeller for all

materials.

- A range of new 2D and 3D beam

elements that provide more functionality have been introduced,

with some becoming the default elements of choice for beam and

frame analysis.

- An updated user interface provides a

more modern look and feel, provides tabs for window selection

panels, easier ways to interact with the view windows, and permits

multiple selection of treeview data for assignment or deletion

purposes.

In summary, this release

contains the following

enhancements:

Design-related

Traffic Load

Optimisation

Analysis-related

Results-related

|

Modelling-related

Element-related

General changes

New worked

examples

|

Design-related improvements

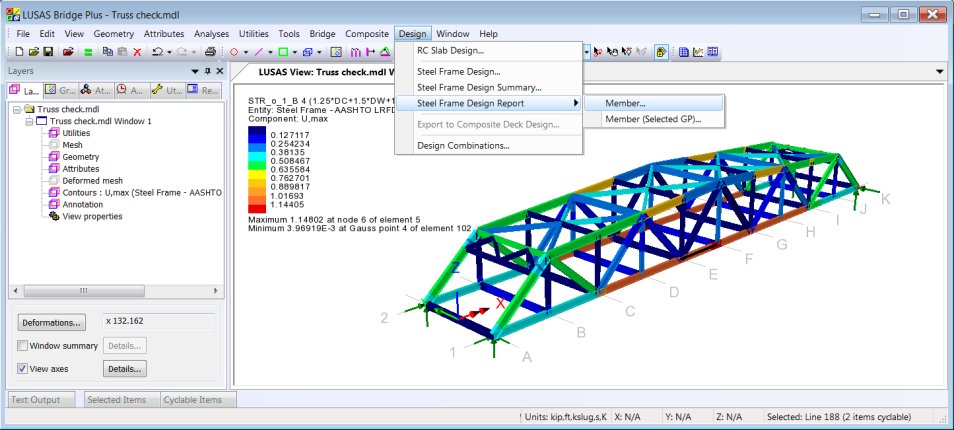

| New

Design Menu

A

new Design menu has been introduced for LUSAS Bridge and LUSAS Civil

& Structural software products. Currently it lists menu

items for RC Slab Design, Steel Frame Design, Export to

Steel/Composite Frame Design, and Design Combinations. A

new Design menu has been introduced for LUSAS Bridge and LUSAS Civil

& Structural software products. Currently it lists menu

items for RC Slab Design, Steel Frame Design, Export to

Steel/Composite Frame Design, and Design Combinations.

Steel Frame Design menu items

will be omitted if a model analysis

category of 3D is not in use, and menu items will be

'greyed-out' if your software licence key does not currently

support them.

Please contact your account

manager if you wish to have access to any licensed options,

and are unable to do so. |

|

Steel

Frame Design

Design

code checking of steel members can now be easily carried out

in LUSAS Modeller. This is performed as a results processing

operation following the solving of a model, and the assignment

of Steel

frame design attributes to lines that represent steel

members, in order to provide design related information for a

specified design code.

The

following design codes are currently supported:

- AASHTO

LRFD 7th Edition (2014) - AASHTO LRFD Bridge Design

Specifications, 7th Edition, American Association of State

Highway and Transportation Officials, 2014.

- CSA

S6-14 Canadian Highway Bridge Design Code - CSA-S6-14,

Canadian Highway Bridge Design Code, Dec 2014, CSA Group.

- EN1993-1-1+A1:2014

- EN 1993-1-1:2005 Eurocode 3: Design of steel structures

– Part 1-1: General rules and rules for buildings.

- AS

4100-1998 Steel Structures (Australia) - Australian

Standard: AS4100-1998, Steel structures, Standards

Australia International Ltd, Sydney.

Design

check results are visualised as Utilisation ratios on a

results viewing layer for a selected design code, and active

loadcase, load combination or envelope. Results components for

individual design checks can be chosen for viewing, and

maximum utilisation factors can also be obtained.

Design

summary reports

A

tabular summary of design check results can be produced for

selected members and loadcases. Results may be saved for use

with Microsoft Excel or saved to a text format. Results can

also be added to a model report, and each time the main report

is generated the design summary data will be updated to match

the current state of the model.

Formatted

member reports

To

investigate the design calculations carried out for particular

members,

formatted design reports can be generated, showing the

calculations made and referencing clauses and equations from

the code. A formatted design report for the selected member

can be added to a model report.

New

worked example

|

Design

Code Load Combinations

The new Design Combination wizard is

used to assign a loadtype to a loadcase, envelope or basic combination

for a supported design code. Based on the assignments and settings

made, load combinations for those load types are automatically

generated by LUSAS Modeller, rather than having to be user-defined

one-by-one.

|

|

|

| Loadcase

/ loadtype definition |

Combination

options

|

Design

combinations created |

Design

combinations for the following codes of practice are supported.

- AASHTO

7th Edition

- AS/NZS

1170

- BD21/01

- BD37/01

- CSA-S6-14

- EN1990

(Buildings) Recommended Values

- EN1990

(Buildings) to Irish National Annex

- EN1990

(Buildings) to UK National Annex

- EN1990

(Bridges) Recommended Values

- EN1990

(Bridges) to Irish National Annex

- EN1990

(Bridges) to UK National Annex

- GB

50009 - 2012

- JTG

D60-2004

New worked example

| RC

Slab design with bending and in-plane effects

The

reinforced concrete slab design facility has been improved to

consider in-plane effects for structures modelled using shell

elements. It supports plotting of contours and values that

indicate flexural reinforcement requirements at Ultimate Limit

State (ULS) or design crack width at Serviceability Limit

State (SLS) for design codes that support this. Calculations

now carried out are for reinforced concrete slabs (without

prestressing) that are modelled using plate or shell elements.

For ULS, both bending only (using Wood-Armer), and bending and

in-plane effects (using Clark-Nielsen) can be considered. For

SLS, both bending-only (using principal moments), and bending

and in-plane effects (using principal stresses) can be

considered, if supported by a chosen design code. The

reinforced concrete slab design facility has been improved to

consider in-plane effects for structures modelled using shell

elements. It supports plotting of contours and values that

indicate flexural reinforcement requirements at Ultimate Limit

State (ULS) or design crack width at Serviceability Limit

State (SLS) for design codes that support this. Calculations

now carried out are for reinforced concrete slabs (without

prestressing) that are modelled using plate or shell elements.

For ULS, both bending only (using Wood-Armer), and bending and

in-plane effects (using Clark-Nielsen) can be considered. For

SLS, both bending-only (using principal moments), and bending

and in-plane effects (using principal stresses) can be

considered, if supported by a chosen design code.

Reinforcement arrangements are

now defined using RC

slab design attributes. Multiple slab design attributes

may be defined and assigned to relevant features on a model.

Values and results contours for

a chosen results component can be displayed for a stated slab

face and for a previously chosen Code of Practice using

standard values and contour plotting facilities. |

RC

Slab design to AASHTO LRFD 7th

The RC slab design facility now

supports AASHTO LRFD Bridge Design Specifications, 7th Edition,

American Association of State Highway and Transportation Officials,

2014.

| Wood-Armer

attribute

The

introduction of Wood-Armer attributes simplifies the

specification of slab reinforcement arrangements. When

assigned to features in a model, they permit calculation of

top and bottom reinforcement moments for shell, plate and

grillage elements, and top and bottom reinforcement forces for

shell elements only according to Wood-Armer / Clark-Nielsen

theory. Multiple Wood-Armer attributes may be defined and

assigned to relevant regions and features on a model. The

introduction of Wood-Armer attributes simplifies the

specification of slab reinforcement arrangements. When

assigned to features in a model, they permit calculation of

top and bottom reinforcement moments for shell, plate and

grillage elements, and top and bottom reinforcement forces for

shell elements only according to Wood-Armer / Clark-Nielsen

theory. Multiple Wood-Armer attributes may be defined and

assigned to relevant regions and features on a model.

|

| Response

spectra provided for numerous design codes

Design code

response spectrum data for use with IMD loadcases can be

defined by selecting the general Utilities > Response

Spectra menu item. The following codes of practice are

currently supported:

- ASCE

7-10 (2010)

- ATC-40

(1996)

- China

GB 50011-2010

- EN1998-1:2004

Design (Horizontal)

- EN1998-1:2004

Elastic (Horizontal)

- FEMA

356 (2000)

|

Material

library enhanced

Supplied library materials are now

accessed by choosing a material type, for a region or country (when

applicable), for design code or standard (when applicable), and for a

grade of material (when applicable). Defined material can now be named

explicitly, rather than have just a system generated name assigned to

it, as in previous versions.

For some materials in some regions a

user-defined grade can also be specified. An example of this would be

for Concrete, USA, AASHTO LRFD 7th, where a compressive strength,

weight, aggregate correction factor, and cement type can be defined.

LUSAS Traffic load optimisation improvements

China

JTG D60-2015

When the country name 'China' and

Design Code 'JTG D60-2015' is selected on the Vehicle Load

Optimisation dialog, traffic loading can now be generated according to

China standards:

- JTG

D60-2015 General Code for Design of Highways Bridges and Culverts,

Chapter 4: Actions.

Denmark -

DS/EN 1991-2 DK NA:2015

When the country name 'Denmark' and

Design Code 'EN1991-2 Denmark 2015' is selected on the Vehicle Load

Optimisation dialog, traffic loading can now be generated according to

Denmark standards:

- EN

1991-2 DK NA:2015 DS/EN 1990/A1 DK NA:2015 National Annex to

Eurocode 0: Basis of structural design, Annex A2 Applications for

Bridges, BaneDanmark/ Vejdirektoratet, 27 Apr 2015.

-

DS/EN 1991-2 DK NA:2015 National

Annex to Eurocode 1: Actions on structures – Part 2: Traffic

load on bridges, BaneDanmark/ Vejdirektoratet, 1 May 2015

-

Annex A (Normative) Load Models for

Classification and Assessment of Load-carrying Capacity,

BaneDanmark/ Vejdirektoratet,

Saudi Arabia -

MOMRA Bridges Design Specifications

When the country name 'Saudi Arabia'

and the Design code 'MOMRA', is selected on the main Vehicle Load

Optimisation dialog, road traffic loading data and parameters can now

be specified with reference to MOMRA Bridges Design Specifications.

Sweden TDOK

2013_0267 (NATO Vehicles)

When the country name 'Sweden' and

Design code 'TDOK 2013:0267 Military Vehicles' is selected on the main

Vehicle Load Optimisation dialog, vehicle loading can now be generated

to aid with military load classification of bridges with reference to

clauses 2.2.1.5 and 1.3 of TDOK 2013:0267 Version 3.0 - Bärighetsberäkning

av broar. UHabb January 2016.

United

Kingdom - BS5400-2:1978 loading added

When the country name 'UK' and Design

code “BS5400-2:1978” is selected on the Vehicle Load Optimisation

dialog, main road traffic loading can now be generated to

BS5400-2:1978 Steel, concrete and composite bridges Part 2:

Specification for Loads, incorporating Amendment No 4209. British

Standards Institution, March 1983.

United Kingdom

- BD37/01 loading added

When country “UK” and Design code

'BD37/01' is selected on the main Vehicle Load Optimisation dialog,

road traffic loading can now be generated with reference to BD37/01.

United

States of America - AASHTO LRFD 7th Edition: Additional State

Implementations

When country “USA" and Design

code “AASHTO LRFD 7th Ed. - <State>" is selected on

the main Vehicle Load Optimisation dialog, road traffic loading can

now be generated with reference to the following new implementations:

- Indiana

- Indiana Design Manual (2013), Indiana Department of

Transportation. The ability to choose state-specific

Permit/Owner-specified vehicles is included on the Optional Code

Settings dialog.

- Louisiana

- LRFD Bridge Design Manual No 2 (June 2016), Department of

Transportation and Development, State of Louisiana. The option to

apply or not apply magnification factor (LADV-11 loading) is

allowed for. When applied, an extra column in the influence dialog

is provided to input the magnification factor (MF) for each

influence.

- Maine -

MaineDOT Bridge Design Guide (March 2014). The ability to choose

between “Maine modified live load” or “Normal HL-93 live

load”, for the Strength I design case is allowed for on the

Optional Code Settings dialog.

- Minnesota

- LRFD Bridge Design (May 2016) Minnesota Department of

Transportation. The ability to choose between 125% or 110% of

HL-93 is provided in the Optional Code Settings dialog. Also the

option of 90% of HL-93 (general AASHTO) is given.

- Nevada -

NDOT Structures Manual (May 2014). The ability to choose

state-specific Permit/Owner-specified vehicles is included on the

Optional Code Settings dialog.

- New York

- NYSDOT LRFD Bridge Design Specifications, September 2011.

Analysis-related improvements

Nonlinear

cable tuning loadcase

The linear cable tuning analysis

facility (which calculates load factors for selected lines in a model

that represent cables in order to achieve defined target values for

various results components) has been supplemented by a nonlinear cable

tuning loadcase option. This can be configured by selecting the Analyses> Nonlinear

Cable Tuning Loadcase menu item. The linear cable tuning analysis

facility (which calculates load factors for selected lines in a model

that represent cables in order to achieve defined target values for

various results components) has been supplemented by a nonlinear cable

tuning loadcase option. This can be configured by selecting the Analyses> Nonlinear

Cable Tuning Loadcase menu item.

Nonlinear cable tuning is for use in

nonlinear analyses where geometric, material or boundary condition

nonlinearity may exist. It is also used for obtaining an equilibrium

state of stressed geometry in existing structures when nonlinear

effects are significant.

Unlike

linear cable tuning, loadcases do not have to be explicitly selected

to be included in a nonlinear cable tuning analysis. Instead, the

position of a nonlinear cable tuning loadcase within the Analyses  Treeview will dictate which preceding loadcase is used to provide

loading data for the cable tuning analysis.

Treeview will dictate which preceding loadcase is used to provide

loading data for the cable tuning analysis.

P-Delta

analysis

P-Delta analysis has now been

implemented for bar, beam, thick and thin shell, and 2D and 3D

continuum elements with GNL capability. P-Delta analysis is an

approximate geometrically nonlinear (GNL) analysis typically used to

take account of the interaction between vertical and horizontal (sway)

loading on tall, slender buildings. Vertical constant loads (usually

dead loads) are used to form the geometric stiffness (stress

stiffened) matrix for the structure; additional live load cases can

then be applied and load combinations used to capture the effects of

the interaction between lateral and vertical loading.

Time

dependent prestress

The multi tendon prestress wizard has

been updated for the AASHTO and Eurocodes to provide an option to

allow for producing details and results of losses at any time, and for

any stage of construction, for supported design codes.

Selection of the new 'Losses based upon

time inputs and calculated stresses' option simplifies and avoids the

previous need to duplicate particular values for Age, material and

geometric attributes that were assigned to the loaded beam. Codified

equations are now used to compute creep and shrinkage coefficients

that were previously difficult for users to define. Values of

"stress at transfer" and "change in stress after

transfer" are now computed from assigned model data by solving

the model at least twice. In doing this, for an initial solve (the

pre-solution), the stress at transfer is assumed to be zero, all

time-dependent losses are assumed to be zero, and the prestress loads

calculated accordingly. In the second (or subsequent) solve, the

stress at transfer is calculated using the eccentricity of each

sampling point, and stresses in concrete read from the results of the

corresponding loadcase in the first (or previous) solution. Selection of the new 'Losses based upon

time inputs and calculated stresses' option simplifies and avoids the

previous need to duplicate particular values for Age, material and

geometric attributes that were assigned to the loaded beam. Codified

equations are now used to compute creep and shrinkage coefficients

that were previously difficult for users to define. Values of

"stress at transfer" and "change in stress after

transfer" are now computed from assigned model data by solving

the model at least twice. In doing this, for an initial solve (the

pre-solution), the stress at transfer is assumed to be zero, all

time-dependent losses are assumed to be zero, and the prestress loads

calculated accordingly. In the second (or subsequent) solve, the

stress at transfer is calculated using the eccentricity of each

sampling point, and stresses in concrete read from the results of the

corresponding loadcase in the first (or previous) solution.

The method of defining prestress prior

to this release can still be accessed using the 'Approximate losses,

requiring input of estimated stresses' option which allows for

producing details and results of short term and long term losses only.

Time

management facility

The time management facility provides

the means to manage a simple construction schedule and easily adjust

the duration of pre-defined construction stages in a staged

construction analysis. It can be accessed using the Bridge> Time

Management menu item. It can also be accessed from the Tendon

Loading Assignment page of the MultipleTendon Prestress Wizard. The time management facility provides

the means to manage a simple construction schedule and easily adjust

the duration of pre-defined construction stages in a staged

construction analysis. It can be accessed using the Bridge> Time

Management menu item. It can also be accessed from the Tendon

Loading Assignment page of the MultipleTendon Prestress Wizard.

It can be used to easily and

automatically update the total response time values in nonlinear and

transient controls that have been previously specified for each

loadcase of a staged construction analysis.

Eigenvalue

buckling of stressed structures

The current linear buckling analysis

facility has been extended so that it is now possible to define loads

that remain constant (dead loads) and those that can vary (live loads)

for the computation of a load factor to cause buckling. Linear

buckling analysis can now also be carried out after a static nonlinear

analysis.

Conversion

of loading to mass for eigenvalue analysis

It is now no longer required to

manually convert loading to mass if any semi-permanent loading is to

be taken into account as part of an eigenvalue analysis. Instead an

option on the eigenvalue control dialog can be selected to

automatically make allowance for this loading. It is now no longer required to

manually convert loading to mass if any semi-permanent loading is to

be taken into account as part of an eigenvalue analysis. Instead an

option on the eigenvalue control dialog can be selected to

automatically make allowance for this loading.

Only loading acting in the direction of

the vertical axis is considered.

Results related improvements

Inspection

Locations

Inspection locations provide the means

to obtain results for user-defined positions of interest on a model.

Model features can have multiple inspection locations assigned to

them. Inspection locations can report results on elements that belong

to the assigned feature, and also those elements that belong to

topologically connected features. Results can be viewed for all

defined inspection locations by selecting the Inspection Locations

option from a relevant results dialog, or for individual chosen

locations. Inspection locations provide the means

to obtain results for user-defined positions of interest on a model.

Model features can have multiple inspection locations assigned to

them. Inspection locations can report results on elements that belong

to the assigned feature, and also those elements that belong to

topologically connected features. Results can be viewed for all

defined inspection locations by selecting the Inspection Locations

option from a relevant results dialog, or for individual chosen

locations.

Improved

averaging of results

Results averaging rules can now be

accessed via the Model Properties dialog or the Model Properties

control object Results averaging rules can now be

accessed via the Model Properties dialog or the Model Properties

control object  in the

Analyses in the

Analyses  Treeview. Averaging rules are common for all analyses. Treeview. Averaging rules are common for all analyses.

By default in LUSAS Modeller, averaging

of results is done for all situations where it is appropriate. Where

averaging is inappropriate, multiple values instead of an averaged

value are now displayed. The new Averaging Options dialog allows users

to state when averaging rules should and should not take place between

adjacent pairs of elements in line, surface and volume features.

Enhanced

averaging for Direct Method Influence analysis

The former requirement in Version 15 to

specify unaveraged or averaged influence results for each

participating element when defining an Direct Method Influence

attribute has been removed. Instead, for Version 16, this decision

will be made automatically. See Model

Properties - Options (Averaging Options) dialog.

Influence attributes defined in and

assigned to a model in Version 15 are unaffected by this new behaviour

because the type of results averaging method that was specified at

the time the influence attribute was generated is defined within

the attribute.

Selective

Results Output

Following results calculation for the

whole model, the results written to a results file can be stated to

either be for all elements, or now, for a specified subset of elements

(those part of a group) within a model. Choosing the latter produces

smaller results files more quickly than would be created for a whole

model.

Improvement

to Graph through 2D facility

A slice section can now be created with

reference to a selected line, arc or combined line, optionally

specifying that the projected length of the line (in a chosen

direction) be used to define the length of slice section line on the

model. In addition line sections can be created from intersecting

surfaces (advanced use) or at the location of an existing graphed

location. When defining the line section by cursor or for lines

generated by projection, the section line created will, by default, be

drawn in the Utilities layer. This may be used later for repeating the

cut if a graph along the same line is required.

A 'Width for corridor averaging' value

can optionally be specified to increase the number of results used

when creating a graph of slice results in order to avoid localised

results concentrations.

Improvements

to Beam and shell / slicing resultants

It is now no longer necessary to have

to view a model along one of the primary view axes prior to defining a

slice location on a model. The slice plane and the orientation of the

slice local axes no longer follow the view's rotation axes. Instead,

the local yz slice plane of the slice path is used to create the slice

planes and this defines the slice local axis.

Multiple beam/shell slice definitions

can now be defined in a single model and are saved as utilities within

the model. The definitions have been enhanced to provide more spacing

options and control over the extent of the model to be sliced.

Results are no longer only displayed

immediately after visiting the Slice Resultants Beams and Shells

dialog. Now, when slice locations are defined and results are

available, results for the slice locations can now be viewed by

selecting the Beam/Shell Slice Resultants entity from the results

properties dialogs (Contours, Diagrams etc). The time taken to produce

beam shell slice results has been reduced.

The Print

Results Wizard is now used to select Beam/Shell Slice Resultants

of interest for viewing in tabular form or adding to a model report

Combination

and Envelope facilities now support User-Defined Results

Beam stresses and results components

defined by the User Defined Results facility can now be used as

primary components when calculating and viewing results for

combinations and envelopes.

Name

scoping for User Defined Results

Name scoping (an association of a name

to an entity, such as a component or variable) has now been introduced

into the User Defined Results facility to help clarify the actual

meaning of an included component or variable. Name scoping is optional

as long as there is no ambiguity. The range of functions supported by

the User Defined Results facility has also been extended.

Print

Results Wizard updated

The Print Results Wizard has been

updated to consist of a single dialog containing all possible results

selections.

The use of the Print Results Wizard is now consistent with

the Graphs and Saved Views facilities with regard to the way in which

generated data can be added to reports by either using: The use of the Print Results Wizard is now consistent with

the Graphs and Saved Views facilities with regard to the way in which

generated data can be added to reports by either using:

- An Add

to Report button

on the printed results window that is displayed.

on the printed results window that is displayed.

- An Add to Report

context menu for the Print Results Wizard

entry in the Utilities

entry in the Utilities  Treeview

Treeview

The summary facility now presents its

output in a consistent, copy and paste friendly, format.

Loadcase

results now generated in a model report using the Print Results Wizard

facility

The Print Results Wizard dialog is now

used from within the 'Add or Edit a Results Chapter' dialog of the

Report facility to add chapters of selected loadcase results to a

model report.

Progress

bar introduced for Modeller results calculation

A progress bar is now displayed at the

bottom of the user interface to show the approximate progress being

made by LUSAS Modeller in calculating results for a particular

task, such as creating a design envelope, or combination. Each

progress step represents one results component being calculated for

one constituent loadcase.

Improved

storing of Modeller-calculated results

Results for Modeller-calculated results

components (such as those calculated for combinations and envelopes,

and also for other derived components such as design code-based

utilisations, Wood-Amer, user-defined results etc.) can be stored in

order to speed-up the initial and subsequent display of those results.

This can be done either by setting options to store calculated results

in LUSAS Modeller interactively, or by specifying that all or selected

results components should always be stored each time a model is

solved.

Modelling-related improvements

New

Modeller User Interface

The Modeller User Interface has been

updated to provide a more modern look and feel, easier ways to

interact with the view windows, and now supports multiple selection of

treeview data for assignment or deletion purposes.

- View

windows now appear with individual tabs for easy selection. These

can be dragged and dropped within the interface to create

side-by-side views.

- Selection

Memory, Selected Items, Cyclable Items, and Visible Items

selection panels are also tabbed and can be activated and

deactivated individually by using the View > Selection Panels

menu item. These panels can now be dragged and dropped to any

location on screen, docked with other panels and set to Auto Hide,

becoming visible again when the cursor is positioned over their

tab identifier. Double-clicking a docked window will isolate it

again.

- Context

menus for each selection panels can be accessed by right-clicking

on the tab heading for each panel.

- Pre-version

16 window behaviour can be reinstated by selecting the Window> Layout> Multiple

Documents menu item.

Multiple

selection of treeview data

- All

Treeviews (with the exception of the Layers

Treeview) now support multiple selection of objects in order

to carry-out an operation on the items, such as to delete a range

of loadcases, or to copy attribute data within the treeview.

Treeview) now support multiple selection of objects in order

to carry-out an operation on the items, such as to delete a range

of loadcases, or to copy attribute data within the treeview.

- In the

Analyses

Treeview multiple loading assignments can now be selected to have

their load factors changed to one common value at the same time by

using the 'Change Load Factor' context menu item.

Treeview multiple loading assignments can now be selected to have

their load factors changed to one common value at the same time by

using the 'Change Load Factor' context menu item.

- Other

selection-specific context menus provide options for each treeview

entry. Only appropriate context menu options are provided for

multiple selected items. For instance a 'Deassign' option may be

provided for a particular entry because it would be valid for all

selected objects, but an 'Assign' option would be disabled because

confusion could occur as the additional assignment data (such as

loadcase or analysis) is often required and may conflict.

- Dialogs

that show treeview-style check boxes (such as used in the Print

Results Wizard dialog) now also support multiple selection.

Model

analysis categories introduced

To prevent potential issues such as

those arising from mixing incompatible elements, and/or mixing

elements with incompatible attributes and options, an analysis

category has been introduced, which must be stated for each model.

Choosing an analysis category of either 2D Grillage/Plate, 2D

Inplane, 2D Axisymmetric, or 3D simplifies the user interface where to

generally show only those menu items, dialog settings and selections

that are appropriate to the type of model being defined. Selecting an

analysis category also defines which startup templates are available

for selection. To prevent potential issues such as

those arising from mixing incompatible elements, and/or mixing

elements with incompatible attributes and options, an analysis

category has been introduced, which must be stated for each model.

Choosing an analysis category of either 2D Grillage/Plate, 2D

Inplane, 2D Axisymmetric, or 3D simplifies the user interface where to

generally show only those menu items, dialog settings and selections

that are appropriate to the type of model being defined. Selecting an

analysis category also defines which startup templates are available

for selection.

Models created prior to Version 16 will

have an analysis category assigned to them automatically by LUSAS when

they are opened (but only where a suitable analysis category can be

established based upon the elements present within the model). If an

analysis category cannot be assigned by LUSAS automatically (perhaps

because a range of now conflicting elements is defined within the

model) a dialog will appear asking for an analysis category to be

chosen.

Model merge

facility Model merge

facility

Model merge allows two or more people

to create separate models of specific parts of a structure (as for

example for different storeys of a building, or different elements of

a stadium) and then combine them at a later date into one master

model. To do this, a previously saved model can be merged with a

currently-loaded model using the File>

Model merge... menu item. The resulting dialog provides options

to specify how the geometry, attributes, loadcases and groups from the

imported model are to be merged with equivalent objects in the

currently open model.

BIM / BrIM File

import / export BIM / BrIM File

import / export

Basic geometry data from third-party

BIM/BrIM files (*.ifc) can be imported to create a feature-based

geometry model in LUSAS. Both BIM/BrIM Structural domain files (*.ifc)

and BIM/BrIM Architectural domain files (*.ifc) are supported for

export.

Compound

section property calculator

Compound sections can be defined from

existing library sections. These can be positioned relative to each

other and can have differing material properties assigned. The

compound section generated can then be assigned to lines in the model

and fleshed in the same way as any other geometric attributes. Compound sections can be defined from

existing library sections. These can be positioned relative to each

other and can have differing material properties assigned. The

compound section generated can then be assigned to lines in the model

and fleshed in the same way as any other geometric attributes.

Concrete

infilled and encased steel sections

The Infill/Encased Section Property

Calculator is provided in Bridge and Civil & Structural software

products only. The following sections are supported:

Filled

box Filled

box

- Filled

stiffened box

- Filled

pipe

- Filled

stiffened pipe

- Encased

hollow box - with rectangular or circular encasement

- Encased

filled box - with rectangular or circular encasement

- Encased

hollow pipe - with rectangular or circular encasement

- Encased

filled pipe - with rectangular or circular encasement

- Encased

I-beam - with rectangular or circular encasement

- Encased

Cross I-beam - with rectangular or circular encasement

- Encased

Combined-T-beam - with rectangular or circular encasement

Chinese

steel section library enhanced

Additional cold-drawn, cold-formed,

hot-rolled and welded sections are now available for selection from

the China section library.

| Improved

arbitrary section property calculation

For thin box sections, only the

points and lines that define the centrelines of the plated

members, and the geometric thickness of each line need to be

initially defined for section property calculation to take

place. Surfaces of a width equal to half of the assigned

thickness are automatically extruded either side of each

line's centreline during the section property calculation

process to determine the correct section properties. These

surfaces can be optionally retained after values are

calculated. For thin box sections, only the

points and lines that define the centrelines of the plated

members, and the geometric thickness of each line need to be

initially defined for section property calculation to take

place. Surfaces of a width equal to half of the assigned

thickness are automatically extruded either side of each

line's centreline during the section property calculation

process to determine the correct section properties. These

surfaces can be optionally retained after values are

calculated.

|

Section

property modification / stiffness reduction factors

Properties affecting the analysis

stiffness of geometric line section properties can now be reduced or

be otherwise modified, whilst leaving their defined dimensions and

section properties intact for design calculations. This is done by

creating section property modifier attributes for each feature type

using the Attributes> Geometric> Section

Property Modifier menu item and then assigning a section

property modifier to selected features for a particular analysis.

Stiffness

reduction factor

A stiffness reduction factor control

option has been provided on the deactivation dialog of the birth and

death facility. This provides control over the amount that the

stiffness matrix is reduced in magnitude when elements are

deactivated. It enables different reductions in stiffness to be

applied to different deactivated elements such that their relative

stiffness is changed, which is useful as a means of controlling the

deactivated elements. For example, it may be desirable for the final

connecting mesh between two cantilevered-out deck ends to have a lower

stiffness reduction factor than the cantilevers whilst deactivated.

Loadcase

dependent constraints

Constraints can now be assigned (and be

turned 'on' and 'off') on a per-loadcase basis. Previously, they could

only be assigned and applied on a per-analysis basis. Amongst many

uses, this will enable the control of the positions of inactive nodes

in a birth and death analysis.

| Perspective

viewing

A

perspective viewing facility has been implemented in Modeller,

and can be obtained by pressing the Perspective button A

perspective viewing facility has been implemented in Modeller,

and can be obtained by pressing the Perspective button  on the main toolbar. It supports feature selection, resizing,

construction grid and page layout facilities. Using a

perspective view allows for more realistic viewing and

'fly-throughs' of a model.

on the main toolbar. It supports feature selection, resizing,

construction grid and page layout facilities. Using a

perspective view allows for more realistic viewing and

'fly-throughs' of a model.

Parameters to control the view

obtained are set on the View Properties dialog. A viewing

angle, which determines the rate at which the perspective

distortion occurs, and a close depth parameter, which

determines how far in front of the view position objects are

removed from the visualisation, can be set. |

| Layout

grids

The infinite regular layout

grid of points as provided in previous versions of LUSAS has

been supplemented with a user-definable layout grid. The infinite regular layout

grid of points as provided in previous versions of LUSAS has

been supplemented with a user-definable layout grid.

Layout grids are typically used

to aid with modelling a 2D layout of a structure, but they can

be duplicated to create multiple grid levels for a 3D model as

for example to provide a setting-out grid for each storey of a

building frame. When layout grids are used, points, lines and

surfaces can be defined by cursor with reference to grid

intersections by a variety of methods, doing away with the

need to otherwise enter coordinates for these features. |

| New

point, line and surface drawing options

A new Geometry > Line> By

Grid menu item allows lines to be defined with respect to

a layout grid. On each

cursor click, a point is created at the nearest grid

intersection. A new Geometry > Line> By

Grid menu item allows lines to be defined with respect to

a layout grid. On each

cursor click, a point is created at the nearest grid

intersection.

New Geometry> Line> By

Grid> Settings and Geometry> Surface> By

Grid> Settings menu items provide access to options to

control how lines or surfaces are created when defining line

or surfaces features with respect to a layout

grid using the new Geometry > Line> By Grid

or the Geometry > Surface > By Grid menu

items.

By clicking and dragging the

cursor to box-select a set of layout grid intersections, lines

or surfaces can be drawn either horizontally in the plane of

the grid, or vertically between grid layouts at selected grid

intersections. |

Section

property modification / stiffness reduction factors

Properties affecting the analysis

stiffness of geometric line section properties can now be reduced or

be otherwise modified, whilst leaving their defined dimensions and

section properties intact for design calculations. This is done by

creating section property modifier attributes for each feature type

using the Attributes> Geometric> Section

Property Modifier menu item and then assigning a section

property modifier to selected features for a particular analysis.

A stiffness reduction factor control

option has been provided on the deactivation dialog of the birth and

death facility. This provides control over the amount that the

stiffness matrix is reduced in magnitude when elements are

deactivated.

Utilities

menu simplified / Tools menu added.

The Utilities menu has been reduced to

now only generally contain those menu items that create a Utility

dataset in the Utilities Treeview. Other items formerly on the Utilities menu now appear on a

new Tools menu, alongside any newly introduced menu items.

Temperature

dependent material properties

Temperature dependent properties of

materials of previously defined, or of new materials can be edited

using the context menu item Edit temperature dependence … for

a material in the Attributes Treeview.

Thermal

loading types rationalised

Thermal loading types have been

reviewed and updated.

Internal

position of shear springs for joint elements with non-coincident nodes

The internal position(s) of the

transverse shear spring(s) for joint elements with non-coincident

nodes can now be defined. Parametric distance factors (between 0.0 and

1.0) can be specified to define the position of the shear spring for

the local y and z directions. This enhancement allows for import of

similar elements from other finite element software.

3D

rotated label and diagram text

Label text for lines and surfaces can

now be optionally drawn to lie along local line axes, or in the local

xy or xz planes.

Similarly, for diagrams, labelled

values can now be drawn in the plane of the diagram, as opposed to

drawing the values flat to the plane of the screen.

Internal

deformed shape of element

LUSAS Solver now computes deformations

at each internal calculation point in each beam element, and these may

be viewed in LUSAS Modeller as contours or a deformed mesh. This means

that the true deformed shape of a line beam can be plotted even if one

line mesh division is used to model the beam. For legacy reasons this

new option is set 'off' by default.

Changes to the Element Library

New 2D

Thick Beam Elements: BMI2 and BMI3

BMI2 and BMI3 are straight and curved

thick beam elements in 2D for which shearing deformations are

included. The elements can accommodate varying geometric properties

along their length. The elements may be used for linear and nonlinear

analysis of two dimensional beam, frame and arch structures.

- BMI2 is

the element selected by default when a 2D Thick Beam linear

element is chosen on the line mesh dialog.

- BMI3 is

the element selected by default when a 2D Thick Beam quadratic

element is chosen on the line mesh dialog.

New

2D Thick Beam Element with Quadratic Cross-section: BMI2X and BMI3X

BMI2X and BMI3X are straight and curved

thick beam elements in 2D for which shearing deformations are

included. The elements have a quadrilateral cross section which may

vary along the element length. The elements may be used for linear and

nonlinear analysis of two dimensional beam, frame and arch structures.

- BMI2X is

the element selected by default when a 2D Thick Cross Section Beam

linear element is chosen on the line mesh dialog.

- BMI3X is

the element selected by default when a 2D Thick Cross Section Beam

quadratic element is chosen on the line mesh dialog.

New

2D Plane Strain Beam Elements: BMI2N and BMI3N

BMI2N and BMI3N are straight and curved

thick beam elements in 2D for which shearing deformations are

included. The element thickness may vary along the length. The element

may be used for linear and nonlinear analysis of two dimensional long

structures of box girder cross-sections such as tunnel linings and

retaining walls for which the plane strain assumption is appropriate.

These elements are compatible with 2D plane strain elements.

- BMI2N is

the element selected when a 2D Plane Strain Beam linear element is

chosen on the line mesh dialog.

- BMI3N is

the element selected when a 2D Plane Strain Beam quadratic element

is chosen on the line mesh dialog.

New

2D Thick Axisymmetric Shell Elements: BXSI2 and BXSI3

BXSI2 and BXSI3 are straight and curved

thick axisymmetric shell elements in 2D for which shearing

deformations are included. The element thickness may vary along the

length. The elements can be used for analysing linear and nonlinear

shell structures which are axisymmetric, e.g. pressure vessels or

pipes.

- BXSI2 is

now the element selected when a 2D Axisymmetric Thick Shell linear

element is chosen on the line mesh dialog.

- BXSI3 is

now the element selected when a 2D Axisymmetric Thick Shell

quadratic element is chosen on the line mesh dialog.

New 3D

Thick Isoparametric Beam Elements with Torsional Warping: BM21W,

BMI31W

Straight and curved beam elements in 3D

for which shearing deformations and torsional warping are included.

The elements can accommodate varying geometric properties along the

length. The elements may be used for linear and nonlinear analysis of

three dimensional beam, frame and arch structures. BMI21W may also be

used as a stiffener for the QTS4 shell element; while BMI31W may be

used as a stiffener for the QTS8 shell element.

New

3D Isoparametic Thick Beam Elements with Quadrilateral Cross-Section

and Torsional Warping: BMX21W, BMX31W

Straight and curved beam elements in 3D

for which shearing deformations and torsional warping are included.

The element has a quadrilateral cross section which may vary along the

element length. The elements may be used for linear and nonlinear

analysis of three dimensional beam, frame and arch structures. BMX21W

may also be used as a stiffener for the QTS4 shell element; while

BMX31W may be used as a stiffener for the QTS8 shell element.

For more information on all these

element types see Element Reference Manual.

Retired

Elements

These elements have been retired

because their use has been superseded by elements with improved

capabilities. Historical models that make use of these elements are

not affected and will still solve. Note that all retired elements do

not appear for selection on drop lists but can still be accessed by

typing the element name into the Line Mesh Attribute dialog.

- BEAM has

been retired and replaced by BMI2, which additionally accommodates

varying thickness, and geometric or material nonlinearity. BMI3 is

also available as a higher order alternative.

- BMS3 has

been retired and replaced by BMI21, which additionally

accommodates varying thickness, product moment of area input (for

non-symmetric sections, strain output, and geometric and material

nonlinearity. BMI31 is also available as a higher order

alternative.

- BTS3 has

been retired and replaced by BMI21, which additionally

accommodates varying thickness,and a higher order variation of

forces and moments along its length. BMI31 is also available as a

higher order alternative.

General changes

LUSAS

installation

The LUSAS installation now follows the

Windows convention.

Changes

affecting LUSAS Programmable Interface (LPI)

All new facilities in Version 16 come

with corresponding extensions to the LUSAS Programmable Interface. See

LPI documentation for more information.

Modeller

Results File caching retired

Modeller Results Files (.mrs) that were

created by LUSAS Modeller to save assembled results and speed up the

results processing of combinations have been retired and have been

replaced in Version 16 with an improved results caching capability.

See Combination

and Envelope Options for more information.

Bridge

load combination wizards for selected design codes retired

The bridge load combination wizards for

the BD37/88, BRO and the Korean Highway codes have been retired. A new

Design Combination wizard facility

has been implemented in their place.

Other

user change requests

In addition to the range of new

facilities and improvements listed, many user change requests have

also been implemented. The originators of all requested changes to the

software (some of which are included in the above list of

enhancements) that have been incorporated in this release will be

notified individually.

Documentation

User manuals

All online and printed documentation

has been updated for this new release. Manuals are provided in PDF

format as part of any Version 16 software download file, and are also

included on the Version 16 software DVD.

New

Worked Examples

The following examples have been

created to illustrate new facilities added in this release.

- Steel

Frame Design to EN 1993-1-1 shows the steps required to

prepare a model for a steel frame design check in accordance with

EN 1993-1-1, and viewing results of member utilisation both as

contour plots and as fully annotated design reports.

- Bridge

Design Load Combinations to EN1990 shows the use of the new

design load combinations wizard to generate factored design

combinations from codes of practice.

Existing worked examples

All examples have been updated to

ensure that the examples match changes made to the software and

incorporate (where possible) new facilities.

Individual worked examples in PDF

format are provided as part of the LUSAS software download file or

release CD, as well as being available from the LUSAS User Area.

Other

Potential

issues opening PDF files referenced in CHM files

On some PCs, and for certain operating

systems, the installation of security updates as released by Microsoft

can affect the opening of PDF files from the table of contents panel

within the CHM file-based help. Any links to PDF files from within

help topic pages may similarly be affected.

If problems are found when attempting

to open these files from within the online CHM file supplied please

note the following:

- Selected

manuals are supplied in PDF format on the installation kit and

these are normally installed into the <LUSAS Installation

Folder>/Programs/PDF_Manuals folder.

- Workarounds/solutions

may be provided by Microsoft during the availability and support

of this particular LUSAS software release.

Previous new facilities and improvements in

this release

None, this is the first release of

Version 16.

|