User Area > Advice

Shape Function Interpolation

Displacement shape or interpolation

functions are a central feature of the displacement-based

finite element method. They primarily characterise the assumptions

regarding the variation of displacements within each element.

Because of their relationship with displacements, the variation

of both strains and stresses is also consequently defined.

The basic assumption of the finite element

method is that the subdivision of a complex physical structure

into the assembly of a number of simple “elements”

will approximate the behaviour of the structure. Because

of this subdivision, each finite element need not attempt

to simulate the complex behaviour of the whole structure

but, rather, assumes a relatively simple displacement variation

so that the sum of the individual finite element responses

approximates the response of the whole structure.

Shape functions are polynomial expressions.

Any order of polynomial can theoretically be used but, in

general, linear and quadratic variations are most common.

It is from the order of the shape function polynomial that

the terms linear and quadratic elements originate.

A consequence of these assumed displacement

variations enables the finite element method to be able

to solve the equilibrium equations at discrete points, thus

transforming a continuous “physical” system (having

infinite degree of freedom) into something manageable for

numerical procedures.

Typically, LUSAS uses Lagrangian shape functions

which provide C(0) continuity between elements (primary variables

only, and not their derivatives, are continuous across element

boundaries). Shape functions are defined in terms of the natural

coordinate system (x) for line

elements (bars, beams), (x, h) for

surface elements (shells, plates, plane membranes) (x,

h, z) and for volume elements (solids).

For many two-noded line elements a linear

variation is assumed as follows

Where N1 and N2

are the shape functions at nodes 1 and 2 of the element

respectively (the order being dependent on the element node

numbering). Diagrammatically, their variation is as follows

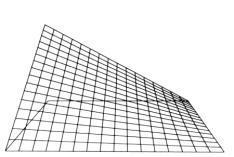

Linear variations are also used on four-noded

surface elements as follows

Three-noded line elements typically

assume a quadratic variation as follows

Where N1, N2 and N3

are the shape functions at nodes 1, 2 and 3 of the element

respectively. Diagrammatically, their variation is as follows

Quadratic variations are also used on

eight-noded

surface elements. The following diagrams show the variations

of the shape functions at both corner and midside nodes

Shape functions need to have the following

characteristics

This means that the value of each shape

function evaluated at its nodal position must be unity.

For example

Requires that the values of each shape function,

evaluated at the other nodes must be zero. That is

The sum of all the shape functions, evaluated

at any point must be unity. That is

Furthermore, to ensure that a finite element

convergences to the correct result, certain requirements

need to be satisfied by the shape functions, as follows

The displacement function should be such

that it does not permit straining of an element to occur

when the nodal displacements are caused by rigid body displacement.

This is self evident, since an unsupported structure in

space will be subject to no restraining forces

The displacement function should be of such

a form that if nodal displacements produce a constant strain

condition, such constant strain will be obtained. This is

essential since a significant mesh refinement will cause

near-constant strain conditions to occur in elements and

they must be able to handle this condition correctly

The displacement function should ensure

that the strains at the interface between elements are finite

(even though indeterminate). By this, the element boundaries

will have no “gaps” appear between them and, hence,

will show a continuous mesh.

The following sections deal with some of

the more frequently encountered practical implications that

are related to the use of shape functions.

Implication: The evaluation of element displacements

The isoparametric

element formulation assumes that

Where {u} are the displacements at any point

within an element and {d} are the displacements at the nodes

of an element.

This equation relates the displacements

at any point within an element to the nodal displacements

according to the element shape function [N]. Therefore,

the displacement at any point (x) in

a 2-noded line element can be obtained from the nodal values

using the following equation

If this element is fully fixed at one end

(d1=0) and sustains a displacement of 2 at the

other end (d2=2), the displacement at the centre

of this element (x=0) would be

given thus

i.e. half the end displacement as expected.

The same can be done with any quantity that

varies across an element, for example, coordinates, strain,

stress, and thickness.

Consider a 3-noded element that uses a quadratic

shape function variation of the form

The quadratic terms (x) in thus giving a corresponding quadratic variation

of displacement over the element. The strain variation can

be defined as

Where [B] is that strain-displacement matrix

and {d} are the three element axial displacements. It can

be seen from the x terms that

the strain is now a linear variation – as will be the

stress variation. In a similar manner, for a linear element,

the strain and stress variation will be constant.

This has a direct bearing on the type of element

to be chosen for an analysis. For instance, consider a bar

element under the action of a constant uniformly distributed

load along the length of the element. The resulting axial

force variation will be theoretically linear as in the topmost

picture of the following diagram.

If this bar is modelled using linear elements

(i.e. linear terms in the shape function), the axial force

will be approximated by a constant, “stepped”

response in each element, since the shape function derivatives

only contain constant terms. A quadratic element (i.e. quadratic

terms in the shape function) will, however, support a linear

response and provide the correct answer directly, since

the shape function derivatives contain linear terms. Thus,

the exact solution can be obtained with a relatively small

number of elements (or even with one element only) if the

actual strain field can be matched by the shape functions

of the element that is being used. In the above example,

the shape function derivative terms did indeed match the

linear strain of the actual analysis.

A frequent observation when inspecting force

output at a simply supported section of a structure is to

find (unexpectedly) non-zero values. Depending on the degree

of mesh refinement, these values can be significant compared

to the peak values. The reason is directly related to the

above discussion. For example, if the force distribution

is at least quadratic in form and linear elements are used

(typically supporting a constant force distribution), a

stepped response will be seen – hence the non-zero

values – these constant values represent an average

of the force distribution and, if summed across the structure

would be found to be equilibrium. The use of quadratic elements

will improve the situation, but even these will not be able

to match 3rd order or higher force distributions

without a measure of mesh refinement performed.

In spite of this sort of discrepancy, it should

be noted that, during the solution stage, the equilibrium

equation is used ({f}= [K] {d}) to ensure that the product

of the stiffness matrix and the computed displacements exactly

balances the externally applied forces. This means that, unless

there are pertinent warnings or errors output during the solution,

static equilibrium will have been fully achieved. Moreover,

the derived quantities of strain and stress will also be found

to be in equilibrium – but not necessarily according

to an expected distribution as noted in preceding paragraphs.

See “Finite

Element Equilibrium” for more information.

Similar difficulties can be observed when

attempting to compare the reactions at a location in a structure

with the element force output at the same location. The

explanation in most cases is, again, related to the order

of shape function that has been used to formulate the element.

See “finite element equilibrium” for more information.

The remedies are to either increase the

number of linear elements used (and reduce the size of the

“step change” between each element) or change

to quadratic elements (to more closely match the actual

variation). The specific element NOTES section in the LUSAS

Element Library Manual will typically give details on the

variation of force that is supported by each element.

Apart from the consideration of element

selection related to the order of shape function, quadratic

elements would be recommended in the presence of high degrees

of plastic strain since they are less susceptible to “locking”.

Linear elements, however, would be recommended when the

stress distributions anticipated are constant or linear.

Such elements are computationally cheaper and, in such circumstances,

render the use of higher order elements unnecessary.

For a discussion on the effects of stress

smoothing (averaging) in the presence of discontinuous stress

fields between elements see “finite

element equilibrium”.

Implication: Nodal Temperature Loading With Temperature

Dependent Materials

Although the temperature loading is defined

at element nodes, it is actually used by LUSAS at a Gauss

point level. The nodal temperature loading is interpolated

from the nodes to the Gauss points using the element shape

functions.

The presence of significant temperature

loading distributions over higher order elements can cause

negative temperature loading to be applied at the Gauss

points – even though the applied temperature field

is entirely positive in magnitude. Such negative temperatures

can be unexpectedly out of the user-specified temperature

dependent material property table.

As an example, consider the situation described

in the first of the following diagrams. The temperature

loading is applied at the nodes as shown.

As a result of the quadratic displacement

assumption used in higher order elements, the interpolation

to the Gauss points yields the variation of temperature

across the length of the element as shown.

This variation will ensure that the applied

temperature loading is applied correctly to the structure,

but for the Gauss points nearest to the zero temperature

specification, a WARNING message will be output to the LUSAS

output file as follows

| ***Warning*** |

Element Number 1, Material Number 1, Gauss Point 1, Temperature Load Of -3.2 Degrees Outside Upper Temperature Bound Of 0 Degrees Specified In Table. The Material Properties Corresponding To The Upper Bound Temperature Are Used |

For most cases the negative value is insignificant

compared to the temperature loading specified and the variation

in the temperature dependency of the material properties.

Mesh refinement in the area of the greatest temperature

variations is the most appropriate method for eliminating

these warnings.

Implication: Element

Thickness Interpolation

Although the thickness for an element is

defined at element nodes, it is actually used by LUSAS at

a Gauss point level. The thickness is interpolated from

the nodes to the Gauss points using the element shape functions.

For a constant thickness element, the interpolation

will always produce the same constant value at the Gauss

points. For a varying thickness over an element, the actual

thickness used will not be that specified at the nodes,

but rather an interpolated value. See the top diagram below.

When using the quadratic displacement assumption

used in higher order elements, the interpolation to the

Gauss points yields the variation of thickness across the

element as shown in the second picture (above). The effect

of a significant variation of thickness over a single element

may, thus, cause a zero or negative thickness value at a

Gauss point. If this occurs the following error message

will be seen in the LUSAS output file

| *Error*** |

Nodal

Or Interpolated Thicknes Is Zero Or Negative |

The remedy is to check that the thickness

variation applied to the specified element is applied correctly.

If so, then the mesh should be refined to reduce the severity

of the thickness variation over the element.

Finite Element Theory Contents

Isoparametric

Finite Element Formulation

Natual Coordinate System

|