Software Option for

Plus versions

Nonlinear Analysis

The LUSAS Nonlinear software option

provides the very latest powerful techniques for solving problems

having either material, geometric or boundary nonlinearity. Nonlinear

stress analysis is becoming increasingly important with designers

employing a wider variety of materials in a multitude of different

applications.

|

Compared to other finite element

systems, LUSAS contains some of the most advanced facilities for

nonlinear analysis that are available today. The Nonlinear option is

particularly effective in reducing the design and computer time

required to solve all types of complex nonlinear problems. Because

LUSAS was initially designed as a nonlinear analysis system, the

features included in the Nonlinear option can be combined with the

other LUSAS analysis options. As a result, the Nonlinear option can

not only be used to solve a multitude of problems having large

deformations, high levels of material nonlinearity and complex

boundary conditions but it can also be combined with the LUSAS Dynamic

and Thermal / Field options to solve

problems in which the effects of time and temperature are important.

The Nonlinear option includes features

such as automatic load incrementation, automatic step reduction upon

convergence failure and flexible restart facilities. These features

enable newcomers to nonlinear finite element analysis to quickly

become proficient in solving nonlinear problems.

|

|

|

|

The robust automatic load

incrementation, arc length and step reduction procedures mean that, in

situations where other systems fail to converge, LUSAS reaches an

accurate solution efficiently. For maximum flexibility any chosen

incremental and iterative strategy may be specified using either load

or displacement control, based on full or modified Newton Raphson

iterations with optional line searches. Fine control is provided by

monitoring the solution using a wide selection of convergence

criteria.

The restart facility enables nonlinear

solutions which have been interrupted or terminated before completion

to be restarted without the need to re-analyse the problem from the

start. When using the restart facility analysis data can be optionally

saved at regular intervals or, for large nonlinear problems where disk

space may be a major consideration, the analysis data maybe saved for

the last converged solution(s). Analyses may be restarted from any

saved data as required.

LUSAS contains a wide selection of

material models for the analysis of elasto-plastic, ductile fracture,

cracking, damage and creep applications. There are nonlinear material

models for metals, plastics, composites, rubber, foam, soils, rock and

concrete. These material models may account for temperature dependent

effects if required. Both isotropic and anisotropic nonlinear material

models are available and material response may be dependent on the

history and direction of straining. The direction of anisotropy is

fully user definable. To ensure a fast and efficient solution the von

Mises and Hill material models use a consistent formulation in the

evaluation of the stiffness matrix which provides quadratic

convergence characteristics. The speed of stress computation has been

optimised by using the latest backward Euler technique. In addition,

material, damage and creep model interfaces are provided so user

defined material definitions may be added as required.

The creep facility allows time

dependent material behaviour to be carried out efficiently. The creep

algorithm is self-starting (it requires no preliminary linear

solution) and automatically computes the most appropriate time step

required in the transient analysis. A wide range of materials may be

modelled by combining the creep algorithm with time independent

plasticity both of which may be temperature dependent. In addition to

the standard creep laws, non-standard laws may be incorporated via a

user-defined creep interface. Note that the dynamic analysis option is

also required in addition to the nonlinear analysis option in order to

model creep.

Geometric nonlinearity needs to be

accounted for when the structure deforms to such an extent that the

original geometry and/or position and direction of the loads

significantly affect the structural behaviour. Many LUSAS elements can

accommodate large deformations and large rotations and the latest

co-rotational formulation ensures that large strains can be

accommodated when necessary.

For analyses with nonlinear boundary

conditions LUSAS has a number of features for modelling contact and

impact. Support lift-off may be modelled using a variety of nonlinear

joint models while a powerful slideline facility helps to simplify the

analysis of all types of general contact problems. The slideline and

slidesurface facility may be used to model general contact between

otherwise unconnected element groups in nonlinear and dynamic

analysis. Typical uses include problems involving friction,

impact/energy absorption and metal forming processes. A tied slideline

option also exists which can be used in linear and nonlinear analysis

to eliminate the need for a transition mesh region between areas of

the model having coarse and fine mesh densities. For sensitive contact

problems in which rapid convergence is difficult to achieve due to

large changes in forces in the contact region a close contact

detection facility is provided. This facility checks for any nodes

that are about to come into contact and creates a transition zone,

cushioning the nodes before full contact is reached. For nonlinear

static analyses where the surfaces of a slideline need to be brought

into contact under the action of the applied loading and interface

forces before the analysis proceeds a pre-contact facility is

provided. This allows the surfaces of a slideline to be defined with a

gap between them. The pre contact facility acts like a magnet in

bringing the bodies into contact to avoid unrestrained rigid body

motion. Boundary conditions can include springs and single or

multi-point constraints.

Loading may be applied as prescribed

displacements, point, distributed or body loading. This loading may be

varied over the structure using a comprehensive variation facility

and/or varied as the analysis progresses using an integral load curve

facility. Both conservative loading (where the load direction does not

change with deformation) and non-conservative loading (where the load

direction changes with deformation) can be applied. Initial or

residual stresses and strains and temperature loading can also be

specified.

In rotating machinery the effects of

rotation can have a significant effect on the natural frequencies of

the structure. Within LUSAS the load correction terms required to

accurately take account of the effects of rotation are introduced by

carrying out an initial nonlinear analysis prior to carrying out a

natural frequency analysis. For structures, such as cables in which

applied loading, initial residual stress, or varying material

properties can significantly affect the structural stiffness a

frequency analysis can also be undertaken after a nonlinear analysis.

In many application areas parts of the

structure need to be added to or removed from the finite element model

as the analysis progresses. Within LUSAS such an event can be

accommodated using the activation and deactivation facility. Any residual forces

present after activation or deactivation of elements can be

re-distributed to surrounding elements under user control. Additional

options allow the definition of relaxation at any boundary together

with the number of increments over which the activation/deactivation

takes place. This facility enables problems such as

general excavation, tunnelling and staged construction of bridges and

other structures to be

accurately modelled.

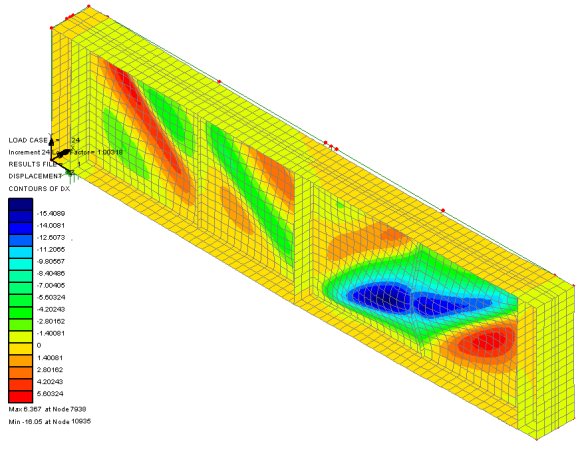

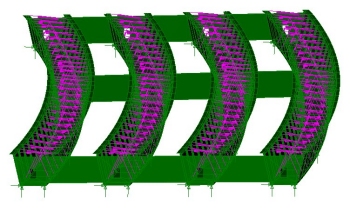

Nonlinear

Buckling

For a detailed structural

buckling assessment a geometrically nonlinear analyses should be carried

out. With this, material and boundary nonlinearity can also be

investigated if found to be required. With a geometrically nonlinear

analysis the stiffness matrix of the structure is automatically updated

between loading increments to incorporate deformations which affect the

structural behaviour (sometimes described by engineers as P-delta

effects). Nonlinear buckling can be performed on the original

structure without imperfection, or by automatically adding an

imperfection based upon a scaled deformed shape which could be from a

linear buckling model.

|

|

|

| A nonlinear buckling analysis with

LUSAS can investigate the stability of girders under self-weight

loading, imposed construction loads such as slab pours, and wind

loads. From the results obtained, members can be re-sized

accordingly and, if necessary, temporary bracing and supports can

be inserted into the model and tested to reduce the structural

response.

See

Additional

Information - Linear - Nonlinear Buckling for more

information. See

Additional

Information - Linear - Nonlinear Buckling for more

information.

|

|

In addition to all the usual powerful

contouring, graphing and plotting features in LUSAS Graphics, a large

number of specific nonlinear results processing features are

available. These include:

- Automatic load-displacement graphs

- Viewing of material yield

- Viewing of concrete crack directions

- Graphing of analysis control

criteria

- Animation of structure deformation

- Visualisation of contact zones and

contact pressure

Find out more

|