Case Study

Stress

and thermal analysis of an LNG marine loading arm

Transferring Liquid Natural Gas (LNG)

from shore to ship and vice-versa at a temperature of -163 degrees

Celsius presents a number of problems due to thermal shock and ice

build-up on the transfer equipment. To help assess the behaviour of

a new LNG loading arm design during cool-down, operation and

subsequent warm-up Woodfield

Systems Ltd (now part of Aker

Solutions) employed LUSAS Consultancy Services. By using

LUSAS Analyst it was possible to prove to the client Abu

Dhabi Gas Liquefaction Co. Ltd (ADGAS) that its request for halving

the cool-down period could be achieved without any detrimental

effect on key components.

|

Overview

The 16 inch nominal diameter

loading arm is a new design to replace existing LNG loading arms

at the ADGAS Das Island Site in the United Arab Emirates. It

consists of a base riser contained within a pedestal fixed to the

jetty and a system of articulated pipes attached to a

counterbalance supporting structure. Swivel joints allow for

movement of the arm in all planes and freely follow the motion of

any tanker when connected. These joints are required to carry high

loads and must not allow any product leakage. Before LNG can be transferred the

loading arm components must undergo a cooling process to prevent

thermal shock. Nitrogen and/or LNG vapour is pumped through the

system initially, before LNG is introduced. To fully investigate the effect of

this cooling process a number of different analyses have been

carried out including Steady-state Thermal, Steady-state

Semi-coupled Thermo-mechanical, and Transient Semi-coupled

Thermo-mechanical using four separate and very detailed finite

element models.

Loading arm

assembly

A 3D model of the whole pipeline

assembly modelled the global behaviour of the system. This highly

complex modelling and analysis process simultaneously analysed the

effect of thermal and structural loads on the product flow-line.

Results obtained confirmed the amount of shrinkage and stresses in

the components as a result of the cooling and highlighted the

importance of using localised models for more detailed analysis.

|

|

|

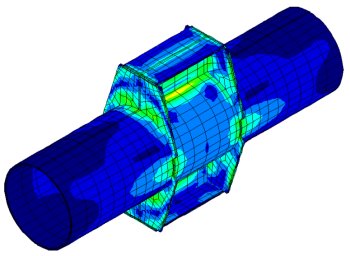

Jetty

pedestal

A 3D model of the pedestal,

top-box, riser, swivels and luff and slew bearings investigated

the cooling effects of the riser pipe on surrounding components. A

conservative steady state thermal analysis was used due to the

convection and conduction effects involved.

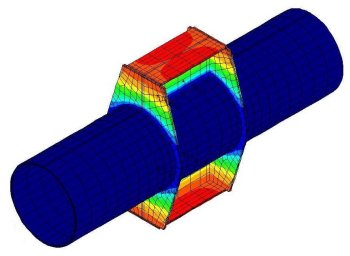

Support

brackets

A 3D model of a support bracket

investigated the extent of cooling and thermal stresses induced as

a result of the relatively rigid circumferential restraint. Whilst

less prone to suffer from thermal shock (as the plates are thin)

the brackets were susceptible to developing a thermal gradient

caused by the plates acting as warming fins on the pipe. As a

result the brackets were subject to further design and modelling

to improve their performance.

|

|

|

|

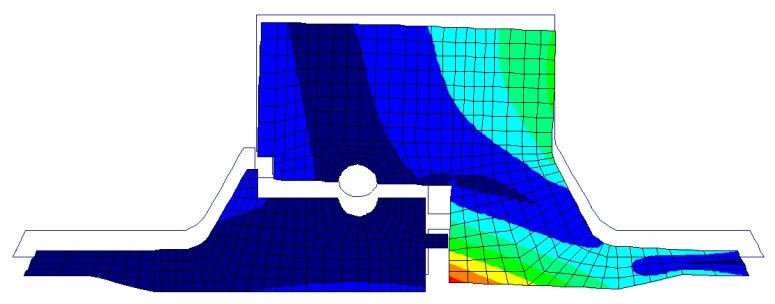

Swivels

A 2D axisymmetric model of a swivel

joint investigated its performance under a variety of transient

thermal loadings. Thermal loadings give temperature profiles and

thermal stresses that vary in time. As a result, graphs of time

temperature histories and plots of von-Mises equivalent stresses

and relative axial displacements for selected nodes on the swivel

easily showed the different stages of the cooling regimes

considered and helped assess whether the seals could maintain

product sealing during cool-down and loading.

Reducing

cooling-down time

The 2D transient thermal analysis

of the swivel showed that the male part cooled much quicker that

the female part due to their relative masses and configuration. To

evaluate different cooling options maximum von-Mises Equivalent

stresses on the most highly stressed part of the swivel were

plotted for comparison and are shown on the accompanying graph.

Red Curve

: An analysis assuming the introduction of LNG liquid with no

prior cool-down period shows why prior cooling is necessary.

Stresses exceed the allowable for the material chosen.

Blue Curve

: A cool-down period of 2 hours (as used on the existing installed

loading arms) using a mixture of nitrogen and LNG vapours produces

the least stress on the swivel when pure LNG is introduced.

Green

Curve : An investigative 1 hour cool-down period of 15

min Nitrogen/LNG mix followed by 45 min LNG vapour cools the

system faster than the the 2 hour regime. However, this causes a

corresponding increase in stress levels resulting in the peak

level at the introduction of LNG being approximately 20% higher.

Pink Curve

: A 1 hour cool-down using only LNG vapour produces the most

favourable result. The system cools faster and whilst the stresses

are the highest initially, the peak stress at the introduction of

LNG is only slightly higher than that caused by the 2 hour regime.

This is the recommended option.

Benefits

By employing LUSAS as an

independent consultant Woodfield Systems were not only able to

confirm or adjust their designs to ensure that they met the best

possible design conditions but were also able to provide complete

confidence to their client that the designs used would provide

trouble free operation, improve vessel turn-around and give

longevity of service.

Other LUSAS Analyst case

studies:

|