Case Study

Analysis

of Barge Gate and Gate Abutment Structures

-

Optimization

of steel plate flood defence gates in New Orleans

-

Noticeably

faster modelling and analysis with LUSAS than previously

obtained

-

Tight design

schedule met

INCA

Engineers Inc. based in Bellevue, WA, is using LUSAS Civil

and Structural to assist with the design of flood protection

structures on two contracts awarded to it by the United States Army

Corps of Engineers (USACE), New Orleans District. By using LUSAS to

help with the design of a floating barge gate and associated

abutment structures the gate design could be optimized to meet

design criteria and a tight design schedule could be met.

|

Overview

On

29th August 2005, Hurricane Katrina, an extremely large and powerful

storm, overwhelmed the flood and storm defences at several locations

in and around New Orleans causing large-scale loss of life and

extensive damage to property. To help prevent future flooding the

hurricane protection system of levees, pump stations and flood gates

that encircle the most at-risk parts of the city is being

strengthened to create a stronger, flood and storm reduction system

that will give a once-in-100-years level of protection.

|

|

INCA involvement

Interim flood protection and the provision of

storm gates at Bayou Segnette Pump Station and the introduction of an

interim floodwall and storm gates along Company Canal in Jefferson Parish

are just two of many USACE contracts that are currently undergoing

design or construction. For Bayou Segnette Pump Station INCA

designed a 30-foot-wide vertical lift gate that would be powered

electrically but also have a manual back up lowering system. For the

Company Canal INCA designed a barge gate that could be floated from

a stored location into its closed storm position prior to a

potential flooding event. Between storm gates INCA also designed a

series of "A-Frames" that provided lateral restraint for

the sheet pile cut off. The estimated construction cost for these

two projects alone lies in the region of $20,000,000.

Barge

Gates and Abutments

The barge gate abutments for the

Company Canal are founded on raked HP14x117 section steel piles

which support a 34’-0" x 16’-0" x 45" thick

concrete pile cap. Steel bracing struts are built into and bolted

onto the pile cap to support the steel wall framing members which

are comprised of steel plate varying between 1/2" and 1"

thickness. The barge gate has a 45 feet clear opening with a sill

elevation at -8.00 and still water level at elevation 9.00. The

barge is approximately 15 feet wide and 47 feet long. When in the

closed position the gate is ballasted down and in-service reactions

are taken by the two steel abutment frames.

Modelling with LUSAS

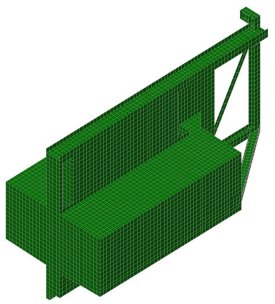

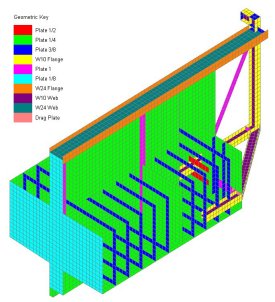

All of the structural features of the

abutments were combined into one LUSAS model using beam, shell and

solid elements to appropriately model each structural element. Use

of the groups facility permitted easy isolation of each structural

type for display and model building purposes and also enabled

customized displays of assigned attibutes to be created as used, for

example, when checking the correct assignment of steel plate

thicknesses - a key requirement for these diaphragm-type of

structures. High and still water

level, gate, barge and impact loadings were all considered in the

linear static analysis that was carried out. A separate LUSAS model

was used to analyse the forces on the floating barge due to

hydraulic loads.

|

|

|

|

|

Modelling of

piled supports |

LUSAS model of

barge gate abutment with pile cap (blue) and steel bracing and

walling (green) |

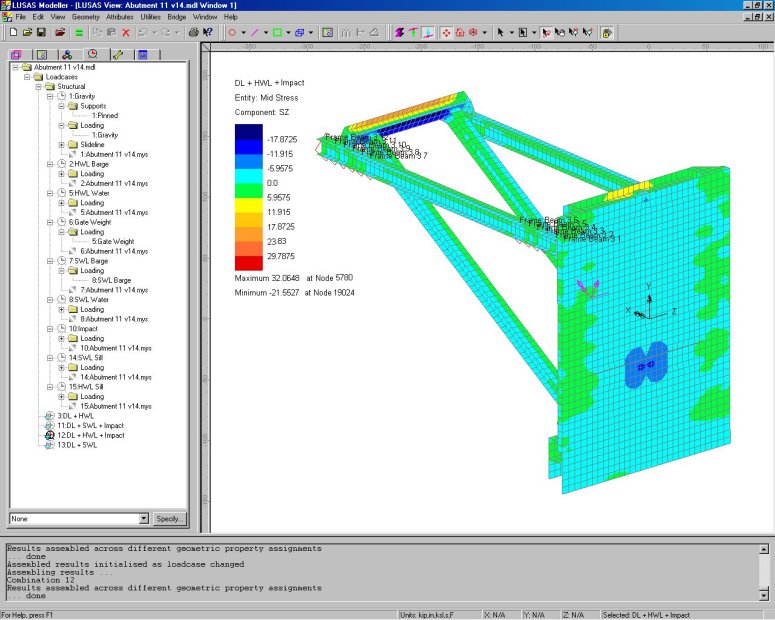

Colour coded plot showing abutment

steel plate thicknesses |

|

|

|

|

|

|

|

Typical load

combinaton stresses in a gate abutment structure |

David Stensby, Structural Engineer at

INCA said: "The barge gate design had to be done under very

tight schedule constraints. The fact that the diverse elements of

the abutment structure could all be modelled efficiently in the same

LUSAS model was especially useful, as indeed was the ability to

accurately model the water pressure loading on the barge

model."

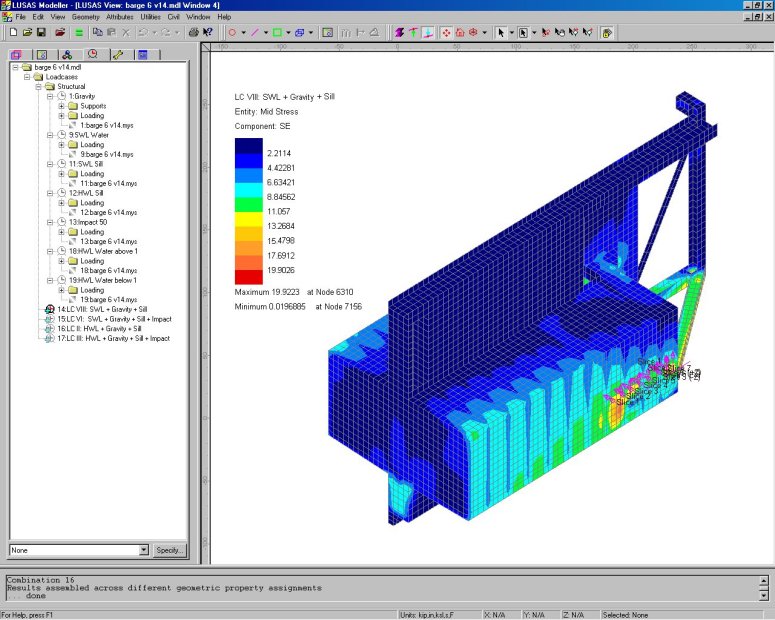

Results

Results for each of the loadcases

were investigated and load combinations were created to derive

combined effects of different permutations of the self-weight, gate,

flood and impact loading. In areas of interest the LUSAS section

slice facility allowed localised stresses to be checked. David

Stensby confirmed the usefulness of the results: "The stresses

and deflections that we obtained from the LUSAS modelling allowed us

to adjust the gate design as necessary to meet the design

criteria."

James Costello, Project Manager at

INCA summed it up as follows: "LUSAS really shined on the

modelling and analysis of these steel barge closure structures and

as a result it helped us to meet the tight design schedule. The time

taken to model these structures in LUSAS was noticeably reduced over

that taken when we previously modelled similar structures with other

analysis packages."

|

|

| LUSAS

model of barge gate |

Barge

gate steel plate thicknesses used

(upstream and deck plates not shown for clarity) |

| |

|

| Typical

load combination stresses in a barge structure |

"LUSAS really shined on the

modelling and analysis of these steel barge closure structures and

as a result it helped us to meet the tight design schedule. The time

taken to model these structures in LUSAS was noticeably reduced over

that taken when we previously modelled similar structures with other

analysis packages."

James Costello, Project

Manager, INCA Engineers Inc.

Find out more

Other LUSAS Civil &

Structural case studies:

|