Case

Study Case

Study

Raising

the roof of the Chunju/Jeonju sports stadium

- global modelling of stadium roof structure

- development of cable stay tensioning sequence

- linear analysis

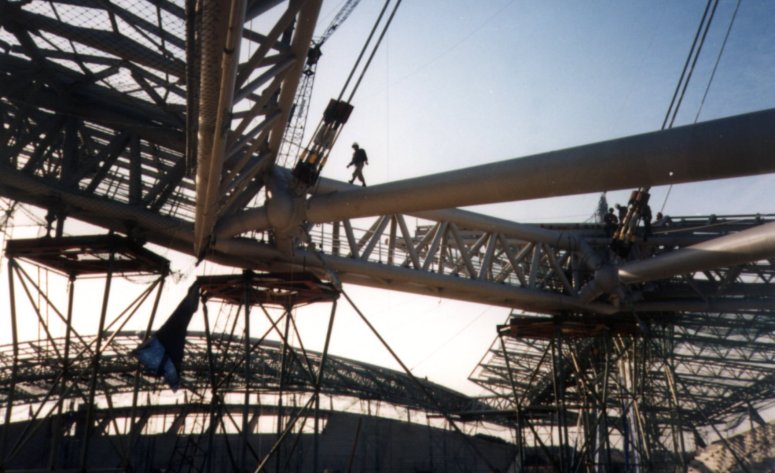

Tony Gee & Partners were retained by steelwork fabricator/erector Hanmaek Heavy Industries Co Ltd

to provide a full erection analysis of the 260m x 160m roof

structure of the 42,000 seat Chunju/Jeonju sports stadium, one of 11 new stadiums

being constructed in Korea for the 2002 football World Cup. TGP's

brief was to define the cable prestressing sequence and the values of prestress to be used

at any given time. The aim was to be able to predict on site and in advance the effect

that tensioning any one cable, or pair of cables, would have on any other cable. TGP chose to use

LUSAS Civil & Structural analysis to help model the construction process

and built a LUSAS model of the complete roof structure

including masts and stays.

Chunu/Jeonju stadium has a

steel roof comprising a perimeter truss supported on A-shaped columns to the rear of the

grandstand and an inner ring truss supported via a fanned cable network on four, 63m high

masts. Because all cable stays have an influence on all other cables

attached to that mast the sequence of stressing the cables and raising the roof from its

erected position was of vital importance to achieve both the correct roof shape and to

avoid any unacceptable locked in stresses.

To simplify the modelling of the 20000 sq. m. space frame roof, models

of individual roof trusses were created to provide equivalent section properties for a

single beam element for use in the main model. Bar elements modelled the cable stays.

Pinned supports were used at the base of the masts. Spring supports modelled the

supporting columns of the pre-cast concrete grandstand around the perimeter. Plain

vertical supports were used at each of the 32 trestle positions where lift-off would

occur. Whilst a nonlinear analysis with lift-off joints could have been carried out

considering catenary effects TGP made a conscious decision to perform a linear analysis

and evaluate support lift-off by using an inspection method. As final tensions are

approached the cable extensions approach the modelled linear behaviour.

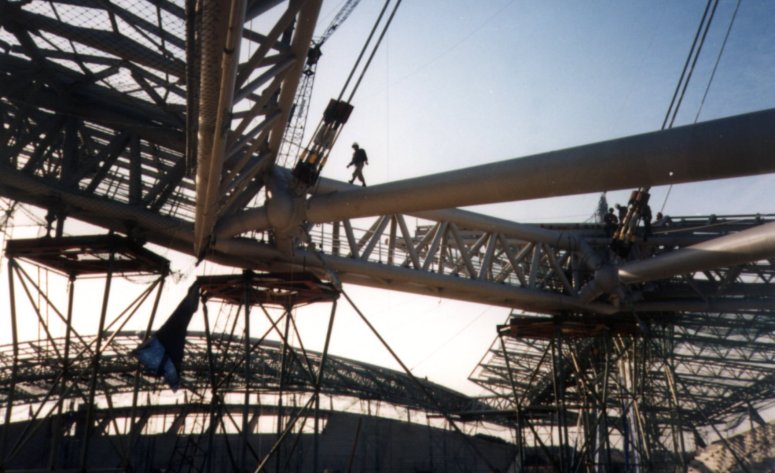

| At each mast 7 cables support the free edges of adjacent roof sections (4 on

the long section, 3 on the shorter section). In addition, 4 cables arranged in a diamond

shape in the plane of the cross beam between adjacent roofs, anchored at the same position

as a pair of cables from the ring truss, together with another pair going out from the

roof to the branch beam at the rear of the mast stabilise it laterally. Cables used are

typically of 65mm and 95mm diameter. The main rear guy at a mast consists of 6, 100mm

diameter cables and carries in excess of 1000 tonnes. |

|

A key part of the analysis was to investigate whether progressive

tensioning all of the cables in one corner could be achieved without affecting other

cables in other corners prior to moving to another corner to repeat the sequence. This had

obvious construction benefits in avoiding the need to move the tensioning equipment around

the site. To test for this, temperature loadings were applied to model the tensioning of

each cable individually. Also, as a check, a unit load was applied to each cable in turn

to see what tensions and compressions it put into other cables (for one corner only). From

these results a matrix was produced which could then be solved for any cable tensioning

sequence.

| David

Barnes, Associate at TGP, explains: 'We looked at each cable in turn because you could

work out what the effect of stressing two cables at once would be by adding the columns in

the matrix together. A unit load was applied to each cable at one corner to work out what

effects that had on all other cables in that corner. We also looked at whether tensioning

one corner would have any effects on cables in the other corners and found that the load

transfer was negligable (less than 2.5%). Therefore the 3D unit in each corner was

effectively self contained and could be stressed independently of the others.' |

|

The inner ring truss is so stiff

that the cables fanning out from

the corner do progressively less and less work and the longest cable is almost

architectural in nature. As a result, tensioning the main load-carrying

cables cables in the corner slackens off the wide fanning cables and leads to a continual

change of tensions throughout the cable system. The permanent works designer had given TGP

a set of final cable tensions that had to be obtained on site and the matrix was solved to

achieve these. Simon Dimmock, engineer on the project said: 'In tensioning the cables on

site we were always going to have a situation where the last cable to be tensioned would

affect all the others, so we had to know what that effect was in

advance - hence the use of LUSAS'. Multiple LUSAS analyses were carried out starting with the roof sitting

on the trestles with no cable tension, before increasing the tension in two cables at a

time up to 25% tension. After all cables had reached this level of tension the sequence

was repeated using tensions of 50%, 75%, 90% and finally using 100% of the tension

supplied by the permanent works designer.

This tensioning sequence was used by Tony Gee &

Partners on site. Because of the linear analysis approach and the absence of modelling the

catenary effects the response of tensioning the cables on site to 25% of final tension did

not reflect the response suggested in the LUSAS model. Later tensioning to 90% and above

matched the LUSAS model far better. The philosophy of the permanent works design was that

once the correct tensioning was applied the roof would simply lift off the trestles -

which it did. Using LUSAS, lift off was estimated to occur at between 80-90% of final

tension and in fact the corner lifted off very slightly before that. Whilst TGP was not

doing a third party check, the process of creating a separate computer model with LUSAS

and having the roof lift off the trestles when the tension specified by the permanent

works designer was input, effectively corroborated their work.

"In tensioning the cables on

site we were always going to have a situation where the last cable to be tensioned would

affect all the others, so we had to know what that effect was in

advance - hence the use of LUSAS."

Simon Dimmock,

Project Engineer, Tony Gee & Partners

Find out more

Other LUSAS Civil &

Structural case studies:

|

Case

Study

Case

Study