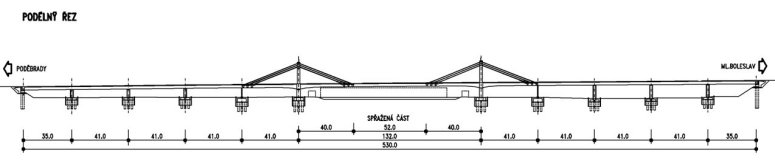

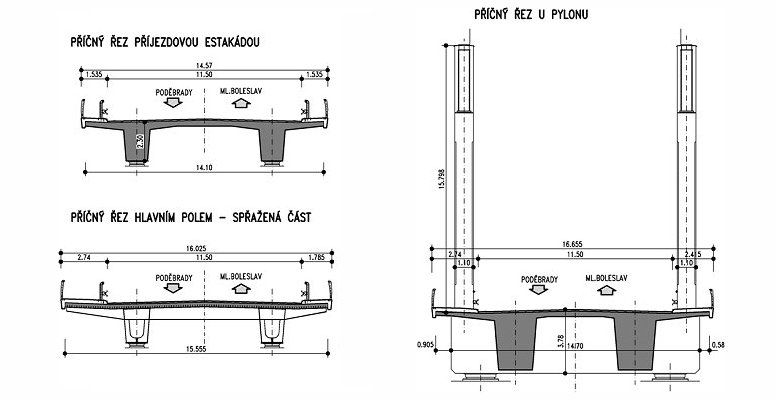

Bridge design The complete bridge crossing has a continuous superstructure 530m long with expansion joints located only at the abutments. The main concrete bridge superstructure consists of a 132m span over the River Labe and two adjacent 41m spans that are directly connected to the approach spans.The concrete deck sections of the main span are of a symmetrical double-girder shape of variable depth and width, and are supported by sets of 3 parallel grouped stays anchored to the 16m high pylons. The middle section of the main span was designed as a relatively lightweight composite steel-concrete drop-in structure. This 52m span comprises two main steel box girders that are tied by steel I section cross beams at 3.0m centres. The thickness of the lower and upper flanges and webs of the main steel girders vary in accordance with the magnitude of the internal forces. After being delivered to site by barges the box girders were lifted into place and welded to 700mm long steel members that were cast into the concrete structure and tied to it using longitudinal prestressing anchors fixed to the end plates. Shear studs tie a 245mm thick reinforced concrete slab to the steel girder structures.

Pylons The 16m high, heavily reinforced concrete pylons are topped with hollow steel plated box chambers for anchoring the cable stays. The anchor plates are one of the most highly stressed parts of the structure and were fabricated from 150mm thick steel plate. Welded into the front face of each anchor plate are six, 377mm diameter, 16mm thick steel tubes through which the stays were passed and then anchored. The bottom flange of the chamber is formed from 50mm thick steel plate with stiffeners to provide a uniform distribution of the forces to the concrete section. The side walls of the box are of 40mm thick plate with 50mm thick vertical stiffeners at the anchor plate locations. Steel studs, welded uniformly to the sides and top of the box chamber, bond the steel box to the self-compacting concrete that was subsequently applied. A 600mm square manhole cover in the top of the pylon provides maintenance access.

Modelling in LUSAS A detailed 3D model of the complete bridge structure including the approach viaducts was created in LUSAS. Solid hexahedral elements modelled the concrete deck and pylons. Thick shell elements modelled the steel members of drop-in span and pylon anchorage boxes. A separate 3D solid element model of a pylon box assembly was also created to investigate the localised stresses in this highly stressed part of the structure.

Eigenvalue analysis obtained the first 15 mode shapes and gave a good indication of the potential response of the structure.

A static analysis investigated the effect of live loads in the transverse direction, and also investigated the effects of any eccentric position of live load on the longitudinal forces induced in the deck and cable stays. Because deck displacement due to off-centre vehicle loading was of interest to Pontex a number of displacement plots were produced showing displacements caused by a variety of applied loads and load combinations. After completion of the bridge both static and dynamic load tests were carried out showing very good correlation with the LUSAS predicted results, effectively verifying the modelling approach used.

Now open The bridge opened to traffic in May 2007. Pontex Consulting Engineers Ltd., believe that because of its location, and by the introduction and use of a number of original structural elements and technologies, the bridge will help contribute to the further development and use of modern light cable-stayed structures in the region and, in turn, become one of the most outstanding bridge structures in the Czech Republic.

"By using LUSAS on this project we obtained an accurate assessment of the deck displacements caused by the static and dead loads. The easy-to-use modelling capabilities and the re-use of previously defined load patterns helped enormously with this." Václav Kvasnička, Consulting Engineer, Pontex Consulting Engineers Ltd. Main parties involved in this project:

This case study was created with reference to a technical paper presented by Milan Kalny of PONTEX Consulting Engineers Ltd. at the IABSE Symposium on ‘Improving Infrastructure Bringing People Closer Worldwide’, Weimar, Germany, 17-21 September 2007. Find out more

Other LUSAS Bridge case studies:

|

|

Software Information

|

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||