Additional Information

See the Software Information

links for general details regarding LUSAS Bridge software products and

options.

Linear / Nonlinear Buckling Analysis

Buckling analysis of structures to

codified requirements is often over-conservative. For existing

structures, assessment or load rating to regional design codes

often shows they ‘fail’ buckling checks, but detailed buckling

analysis with LUSAS can often reveal additional ‘hidden’

capacity. For new plate girder, box or tub

girder bridge designs, linear and nonlinear buckling analysis

using LUSAS can investigate the girder stability during erection,

look at the effects of a slab casting sequence, and also help to

optimise the size of the web and flange plates, bracing,

stiffeners and position of any temporary supports used.

Linear buckling

To obtain an indication of a structure’s

potential to buckle under a particular loading a linear buckling

analysis can be undertaken. Linear buckling analysis can estimate

the maximum load that can be supported prior to structural instability

or collapse. A LUSAS analysis therefore provides load factors based on

classic elastic buckling. Where the type of structure isn’t covered by

the design code, and where P-delta, lift-off and yielding effects are

not significant in the loading range up to buckling, a linear buckling

analysis should give a more accurate assessment of member resistance

than would be obtained from a code of practice. However, imperfections

and nonlinearities tend to prevent most ‘real’ structures from

achieving their theoretical elastic (or "Euler") buckling

strength, so the eigenvalue buckling load factors are therefore somewhat

overestimated. To get a more accurate answer nonlinear analysis can be

undertaken.

|

|

|

|

Nonlinear buckling

For a detailed structural buckling

assessment a geometrically nonlinear analyses should be carried out.

With this, material and boundary nonlinearity can also be investigated

if found to be required. With a geometrically nonlinear analysis the

stiffness matrix of the structure is automatically updated between

loading increments to incorporate deformations which affect the

structural behaviour (sometimes described by engineers as P-delta

effects).

Nonlinear buckling can be performed on the original structure

without imperfection, or by automatically adding an imperfection based

upon a scaled deformed shape which could be from a linear buckling

model.

|

|

|

A structure may also experience some

material nonlinearity during a buckling event (yielding for example)

and/or some boundary nonlinearity (lift-off supports, perhaps).

Generally it is recommended that modelling of nonlinear effects is done

progressively in order to evaluate the results of each additional

modelling at each stage. This helps in developing an understanding of

the structural behaviour and helps to identify the cause of any

potential failed analyses.

|

|

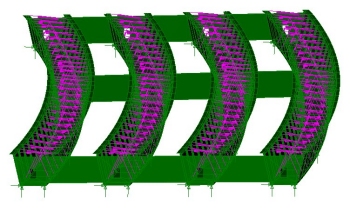

Erection

analysis

A nonlinear buckling analysis with

LUSAS can investigate the stability of girders under self-weight

loading, imposed construction loads such as slab pours, and wind

loads. From the results obtained, members can be re-sized

accordingly and, if necessary, temporary bracing and supports can

be inserted into the model and tested to reduce the structural

response.

For some clients, buckling analysis erection checks with

LUSAS have highlighted that for some open box girder designs with

narrow bottom flanges a standard design approach is just not

valid.

|

|

|

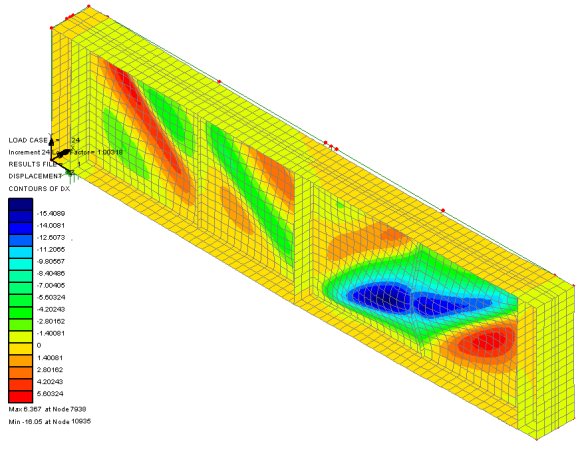

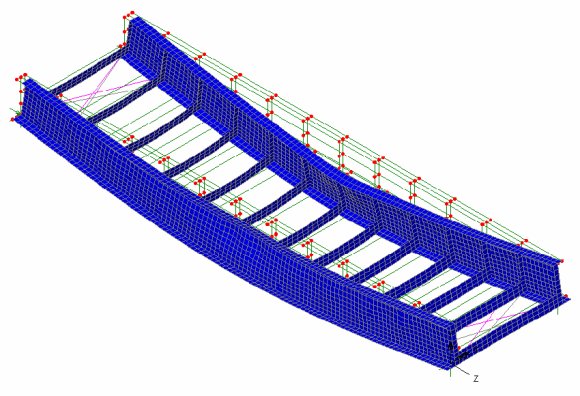

Mesh

sensitivity analysis

With finite element analysis, it is

good practice to carry out a mesh sensitivity check to ensure that

results are not unconservative. Mesh density should be checked to

ensure enough elements of the type chosen are being used. Coarse

mesh patterns could produce under conservative results; fine mesh

patterns may take longer to solve and be no more accurate.

Similarly quadratic elements will generally produce better results

than linear elements with nonlinear capabilities. Unlike some

software systems, with LUSAS, mesh patterns can be easily refined

and manipulated without losing any assigned supports and loading -

making it ideal for this type of work.

As an example the plate girder

shown was meshed with 0.2m mesh divisions and then had 0.1m mesh

divisions assigned for a mesh refinement check. The results showed

that the change of displacement and the difference in maximum

stress differed by less than 1% - meaning that, for this model at

least, the initial mesh definition was sufficiently fine enough to

achieve good results.

|

|

|

|

Nonlinear

buckling analysis procedure with LUSAS

- Carry-out an initial linear

analysis and check the stress levels for factored loading.

- Perform a mesh sensitivity

analysis

- Run a linear

eigenvalue buckling analysis to give load factor at which the

critical buckling may occur.

- Save the model and define an

initial imperfection (if necessary)

- Add nonlinear controls

- Run an initial geometric

nonlinear buckling analysis

- Add additional nonlinear

material or boundary conditions as necessary.

|

|

Buckling analysis

summary

- Linear buckling analysis enables

an assessment of the buckling resistance of a structure, and may

be particularly useful for structures not falling within the

scope of codes of practice.

- In some instances, a linear buckling

analysis may appropriate to satisfy checks against buckling, in

others, it may only provide a good starting point for a thorough

nonlinear buckling analysis.

- Nonlinear buckling analysis

provides a detailed buckling assessment and can include

geometric, material and boundary effects.

- LUSAS provides all the facilities

required for linear or nonlinear buckling analysis, and has the

ability to consider nonlinear buckling effects throughout a

staged erection analysis.

|

|

|

Software Information

|