Case Study

Automated

Design of Railway Culverts

-

Automated design/checking of

culverts using scripting

-

Detailed

calculation option

-

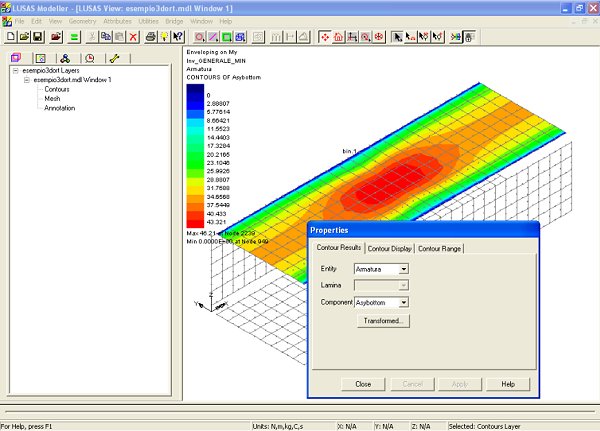

Reinforcement contour plots

Italian LUSAS distributor Alhambra

srl worked in conjunction with the engineering company Ingegneri

Associati srl to automate the modelling and design/checking of

railway culvert structures in

accordance with Italian bridge loading and reinforced concrete codes

of practice. Automating the analysis of culvert structures

using the LUSAS Programmable Interface scripting facilities produces significant time

savings over manual methods, improves the quality

of the analysis and also produces a detailed analysis report.

|

Culvert Design

Wizard

The

Culvert Design Wizard uses a number of user-defined dialogs to

obtain all the data required for a culvert analysis. First,

transverse culvert geometry is defined along with water levels (if

any) and whether a road is present in the culvert. This is

followed by specifying plan dimensions and the angle of any rail

lines crossing the structure. Error checking and incompatible data

entry is provided on all dialogs. An option is available to

undertake a more traditional 2D analysis considering a strip of 1m

width or to define a full 3D model of the structure using thick

shell elements.

A series of dialogs enable the following data

to be entered:

|

|

|

|

|

Cross-sectional

dimensions including:

-

Number and position of tracks

-

Angle between the railway line

and the longitudinal axis of the culvert

-

Angle between the lateral

faces and the longitudinal axis of the culvert

Material properties

-

Concrete properties (linear

elastic material)

-

Ground/Soil properties (modelled

as loads or linear elastic springs)

-

Availability of different

stiffness for vertical springs under the structure (using

LUSAS variations), and of horizontal springs on vertical

walls

|

|

Centrifugal, thermal and shrinkage

actions

-

Principal or secondary railway

line

-

Options for curved railway

lines, relative transverse difference in height between

rails Eb, and train design speeds

-

Thermal and shrinkage actions

A LUSAS model file is created from

the data entered with the structure having rigid zones at nodes

and with all load conditions required by the design code included. All

transverse actions are considered to act in the same direction.

|

Results processing

The LUSAS Smart Load Combination

feature is used to include all load combinations included in the

Italian design code for railway bridges and a global envelope is

produced.

Train loads are considered at three possible positions

for each railway line - each edge of

the culvert and at the centre of the span.

|

|

Design/checking

options

Nodes on the model where a detailed

calculation is required can be selected. Details of concrete and

steel design stresses are entered along with details of minimum

steel area, planimetric layout, and of steel cover for each

member. Using a Wood-Armer approach, the minimum amount of steel

area needed to comply with the requirements of the Italian design

code is calculated. Steel areas of transverse and longitudinal

steel bars can be plotted on selected parts of the culvert.

Detailed Report

A Microsoft Word report provides a

complete description of the data input and load combinations used

in the culvert analysis and is an important contribution to the

speed-up process and the quality of the results presentation. It

provides a comprehensive listing of all model information and

results details and allows the design engineers the opportunity to add their

own comments and additional information. A contour plot of all

stresses for final maximum and minimum envelopes activated

according the most relevant stresses is also included along with a

contour plot of steel area needed in each direction and in each

part of the structure. If any user-defined nodes have been

selected on the model for detailed stress calculations then these

appear in the report also.

Benefits

Carlo Margheriti of Alhambra srl

said: The script we developed significantly speeds up the analysis

of a typical "simple" structure, such as a railway

culvert. By modelling the structure with exact 3D geometry and

supports, and including all the loading combinations prescribed by

the code of practice the quality of the analysis is improved

significantly also. He continues: A simplified 2D strip

analysis option is also provided to comply with client wishes and

to help check or assess third party calculations that use the same

design assumptions.

"The script we developed

significantly speeds up the analysis of a typical "simple"

structure, such as a railway culvert ... and the quality of the

analysis is improved significantly also."

Carlo

Margheriti, Manager, Alhambra srl

Find out more

Other LUSAS Bridge case

studies:

|