Case Study Case Study

Wichita's

Riverfront Footbridges

-

Staged

erection engineering analysis of two post-tensioned bridges across the

Arkansas and Little Arkansas rivers

-

3D linear

and nonlinear analysis

-

Cable

tensioning optimized giving reduction in

contractor's build time

As part of Wichita's

riverfront development program, two cable-stayed pedestrian

bridges are being constructed to extend the city's cycle network

and provide better access to the surrounding neighborhoods and

business attractions. The bridges' contractor, Dondlinger &

Sons Construction Co., Inc., retained Genesis

Structures to analyze the staged erection process and

prepare the erection manuals required for each of these complex

cable-stayed bridge structures. Genesis Structures used LUSAS

Bridge analysis software to carry-out numerous detailed 3D linear

and nonlinear analyses of the bridges and their components to help

minimize the number of steps in the cable tensioning process and

reduce the Contractor's time and labor.

Overview

|

The

city of Wichita, Kansas, boasts a bike and pedestrian transportation

system that covers more than 150km, much of which runs through parks

and along its rivers. As part of its riverfront corridor improvement

project, two new bridges spanning 320 feet and 240 feet will

cross over the Arkansas and Little Arkansas Rivers respectively at the site of the

"Keeper of the Plains," a 45 foot high, raised, iconic Indian

statue. The bridges connect Exploration Place, a modern, interactive

science museum, with the culturally significant Mid-America All-Indian

Center. Because of their location, the cable-stayed bridges

incorporate tapered towers and a unique stay-cable configuration that

mimic feather shapes and other patterns found in Native American

headwear.

|

|

Bridge construction

Each bridge is comprised of a 120 foot

high steel tower of 60 inch triangular cross-section that supports

precast concrete box segments that are initially built on falsework

bents and then longitudinally post-tensioned together.

Each tower is

formed from two, 60 ton steel leg segments that are lifted into

position using a specially designed lifting saddle and integral

lifting lug. A 30 ton upper cable anchorage unit sits on the top of

both tower legs. This anchorage was assembled at ground level for ease

of installation of the bolted connections and then raised atop the

legs using special rigging. Adjustments were made using a screw jack

system to obtain the correct tower leg positions prior to final

assembly. Partial penetration welds around the full perimeter of the

upper ends of each leg and the unit secure it in place.

Decks are constructed of 32 foot long,

hollow box segments having a maximum depth at the bridge centerline of

48 inches and tapering to a 24 inch visible profile. During assembly

each segment is placed on steel falsework bents that allow

longitudinal movement of the segments during placement and

longitudinal post-tensioning. Ten inclined cable pairs support the

longer span bridge deck and eight cable pairs support the shorter

bridge. Main stay cables (provided by CBSI, Inc.) are 2 inches diameter with back stay cables of

3 3/8 inches diameter ASTM A586 Structural Strand.

Staged erection

analysis

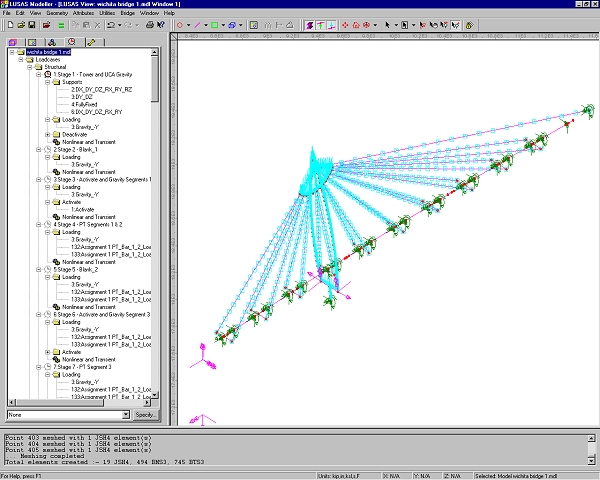

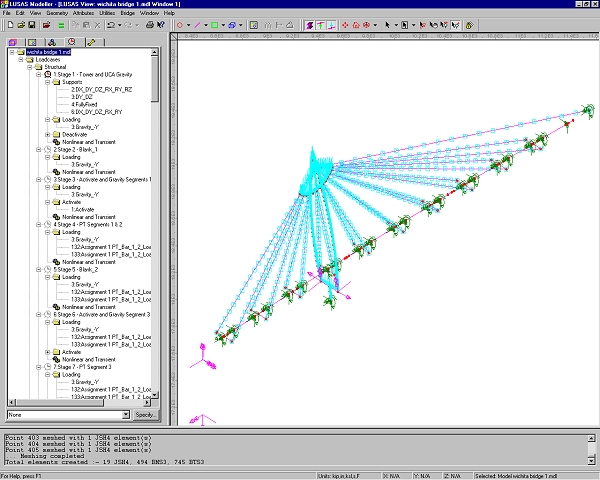

Analysis with LUSAS was required to

model the complex erection sequence involving falsework construction

in the river, post-tensioning of the precast concrete deck system, and

sequential cable tensioning to lift the structure from its temporary

supports to create the free-spanning cable-stayed spans.

Project specifications required that

the bridge geometry be set-up at the beginning of its service life to

obtain the target geometry after 10 years of service. To accomplish

this, time-dependent effects due to creep and shrinkage in the

post-tensioned concrete deck segments had to be evaluated. This was

achieved by using the CEB-FIP 1990 creep and shrinkage material model

in LUSAS.

| After

tower erection each of the 32 foot long deck box segments were

constructed upon structural steel falsework bents and initially

post-tensioned together for continuity using four, 1" diameter

post-tensioning bars. Following the complete longitudinal assembly of

the segments, four 19 strand, 0.6 inch diameter tendons were

installed and tensioned to obtain the required compression in the deck

system prior to cable installation. The LUSAS post-tensioning wizard

was used to model the erection of the deck segments at each stage of

the construction.

|

|

Preliminary tensioning of the stay

cables in the LUSAS model was accomplished through initial strain

loading of the nonlinear beam elements representing each cable. During

the actual stay-cable installation, the longitudinal concrete deck

system was to be lifted from its temporary supports through a

carefully planned installation sequence. The falsework system was

required to allow longitudinal movement and shortening of the deck

system as well as unrestrained lift-off from the supports. Modeling

for these effects was accomplished through the use of nonlinear joint

element supports in LUSAS. Final tensioning of the stay cables was

achieved by applying a negative temperature load to each cable pair to

obtain the desire tension. Excellent correlation was obtained between LUSAS

predicted cable tension values and on-site measurements.

3D solid modelling of

box segments

| Each

of the box segments contained access openings in the top slab to

provide access for the installation of the longitudinal

post-tensioning system as well as for two tuned mass dampers (provided

by Motioneering, Inc.) to control pedestrian-induced vibrations.

Openings for the tuned mass dampers exceeded 15 foot in length and

created areas of discontinuity in the top slab during lifting

operations and longitudinal post-tensioning. To verify that each of

these locations provided adequate continuity, individual segments were

modelled using 3D solid elements and checked for both lifting stresses

and longitudinal stresses due to post-tensioning.

|

|

3D

modelling of tower

|

The unique tower design of these

bridges creates a highly confined compression and flexural zone

immediately below the upper cable anchorage. To ensure adequate stress

transfer brought on by the cable tensioning, a 3D LUSAS model of the

entire tower and upper cable support was developed to determine the

local zone effects in this region. Confirmation of the local stresses

was obtained prior to proceeding with the complete analysis.

"We used LUSAS Bridge exclusively

for the erection engineering of the Wichita Bridges and obtained

excellent correlation between the on-site cable stayed measurements and the

values that LUSAS predicted for lift-off"

Dr. David Byers,

President, Genesis

Structures.

View

an animation of the staged erection engineering sequence View

an animation of the staged erection engineering sequence

|

|

Find out more

Other LUSAS Bridge case studies:

|

|

Software Information

|

Case Study

Case Study