Case

Study Case

Study

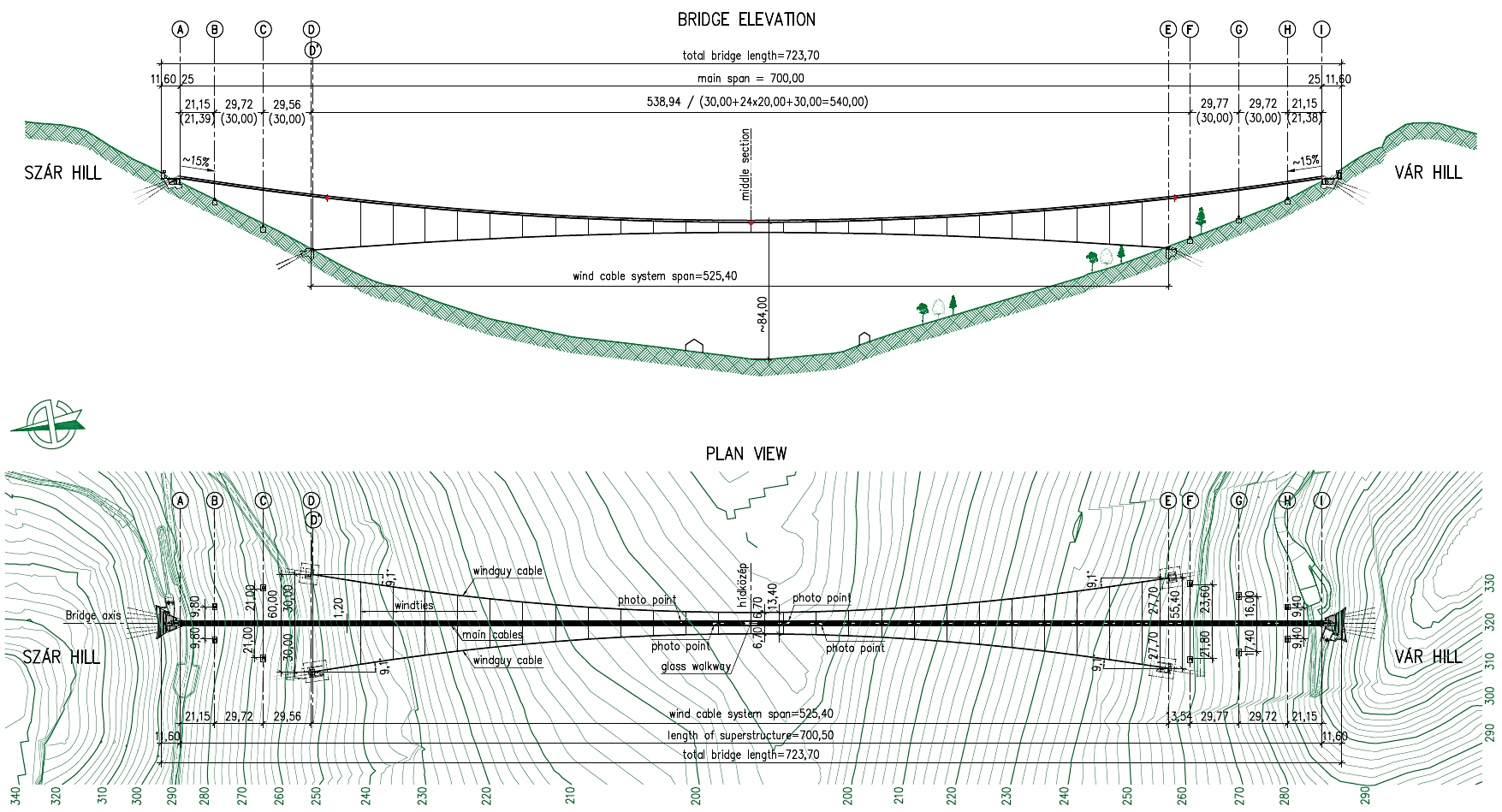

Zemplen 723 footbridge

- World record-breaking

pedestrian catenary bridge

- Detailed geometrical nonlinear

staged construction analysis

- Analyis accuracy proven by

on-site measurements during and after construction

MSc

Engineers and Consultants Ltd. used LUSAS Bridge analysis

software to assist with its design of a world record breaking

pedestrian catenary bridge on behalf of its client the Municipality of

Sátoraljaújhely.

The bridge is a new attraction for the Zemplen Adventure Park, and

spans 700m between two hillsides of the Zemplen Mountains, in Sátoraljaújhely, Hungary.

On completion in June 2024, it became the longest span bridge of its kind

in the world. Its total length (including the abutments with glass balconies) is

723.7m, giving the bridge its name of Zemplen 723.

Bridge description

Zemplen 723 is a catenary bridge, meaning that compared to classic suspension bridges it has no pylons and hangers so the elevation of the pedestrian deck follows the parabolic shape of the 6 main cables.

At its midsection, where there is a glass floor, the 1.2m wide two-way walkway sits approximately

84m above the valley floor. The bridge is stiffened by a wind cable system

consisting of two primary wind guy cables and secondary wind tie cables. The two main

wind guy cables run in a parabolic shape in a tilted plane towards the bridge.

Additional fixed anchor cables are provided at the starting sections of the bridge. The large tensile forces

of around 3300kN in each of the 6 main cables are carried by steel structures integrated into the

reinforced concrete abutments. The overall static equilibrium is ensured by 23m

long strand anchors embedded into the dacite rock. The construction required 149

tonnes (6490m) of steel cable and an additional 96 tonnes of structural steel. The substructures (abutments and wind cable substructures) consist of 1700m3

of reinforced concrete.

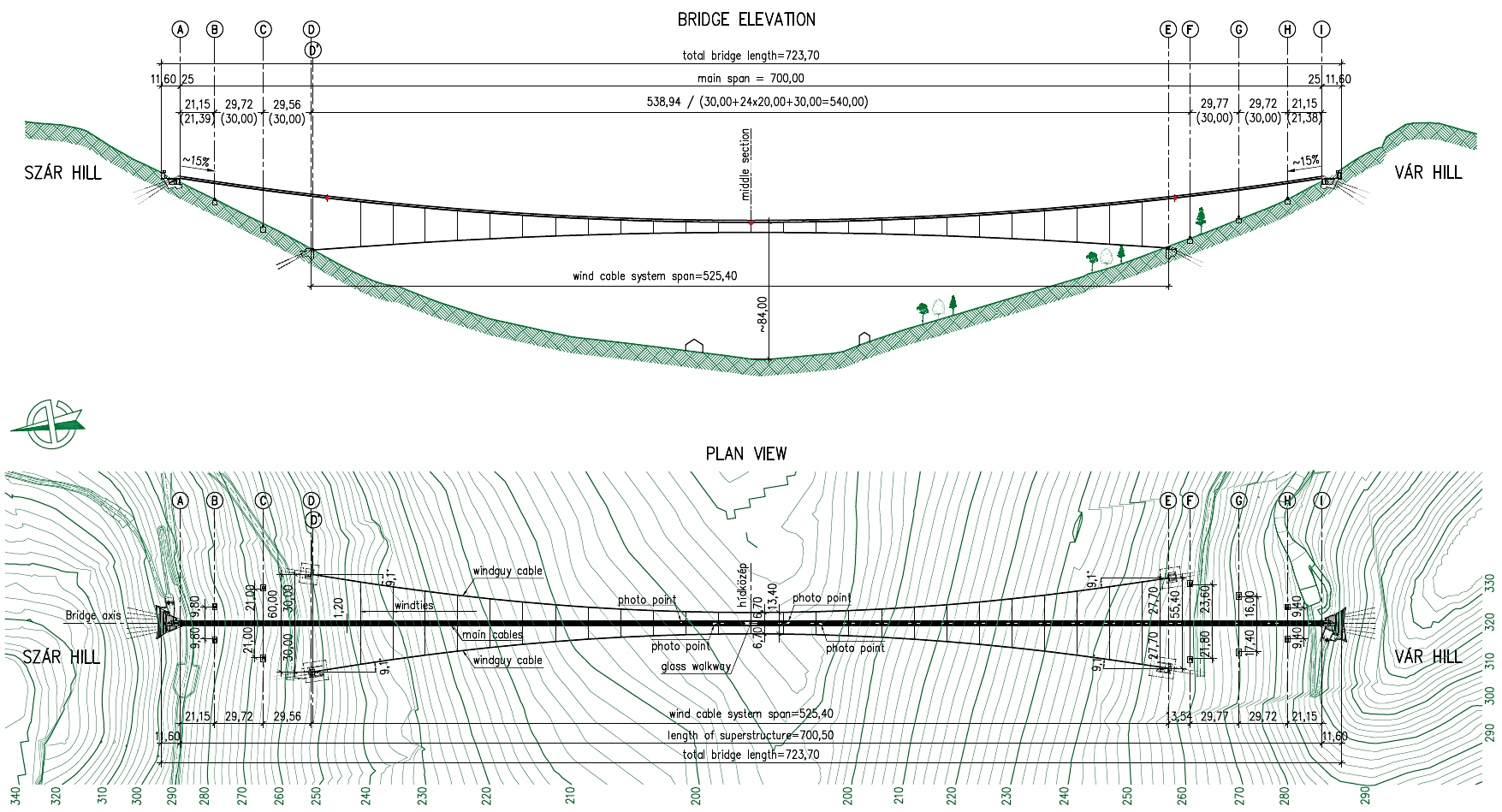

General

arrangement

(click for higher resolution image)

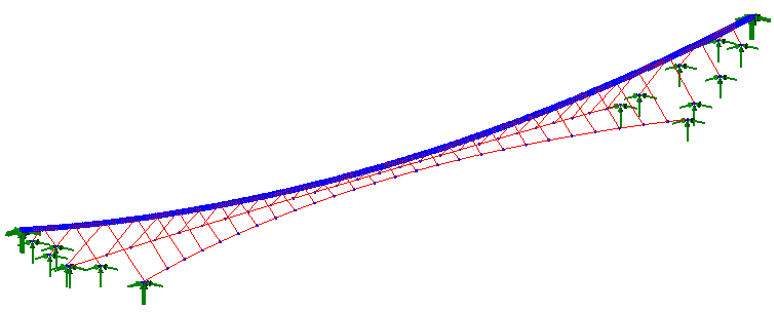

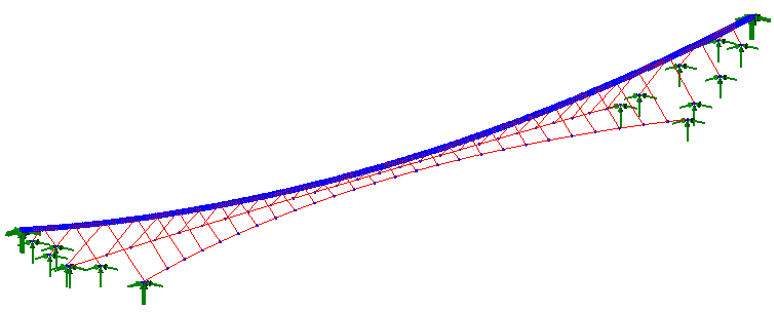

Modelling with LUSAS

The bridge design required a geometrical nonlinear staged construction

analysis in order to take into account the large displacement and the exact force development of the cables.

Because of its capabilities for this type of analysis a LUSAS finite element model was

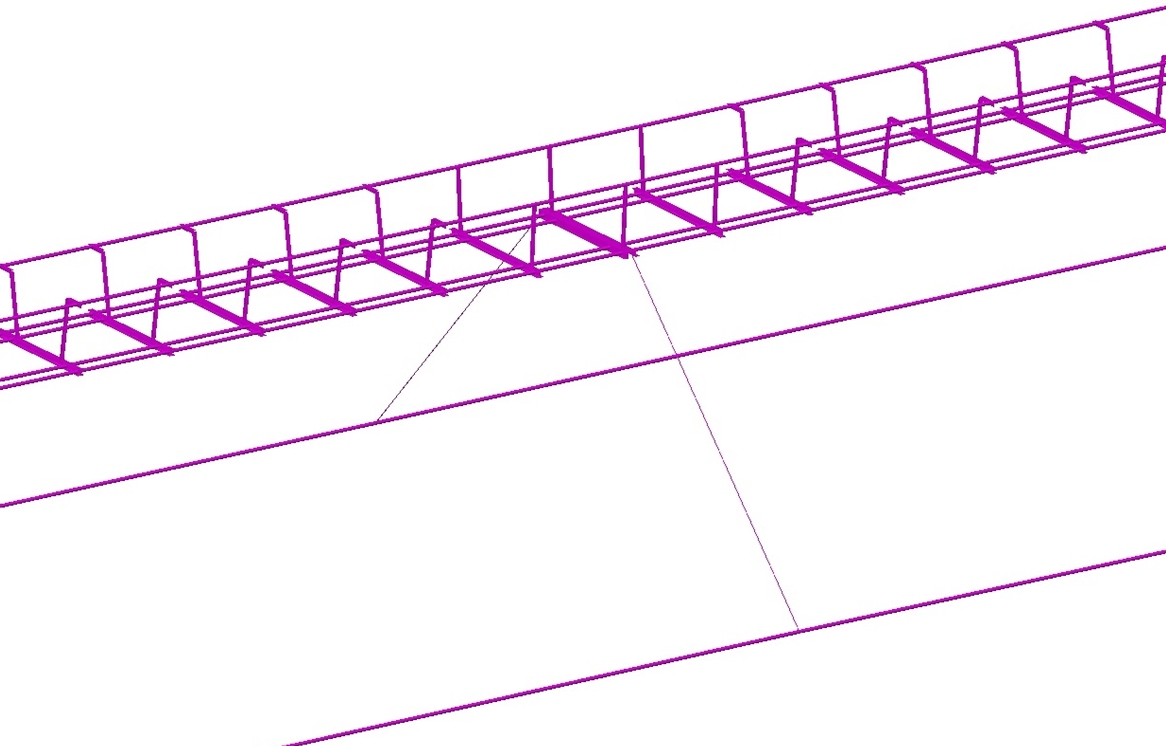

built using bar elements to

represent the cables and beam elements to model the supporting frame elements of the bridge deck.

|

The final geometry of the wind cable system was determined by parametric analysis. The form finding procedure was carried out by a script which was written with the help of LUSAS’s step recording feature.

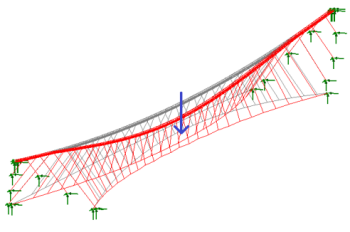

As part of the design procedure a thorough physical wind analysis was also carried out. The eigenmodes and eigenfrequencies,

required as initial data for the wind analysis, were obtained from the global LUSAS model results.

|

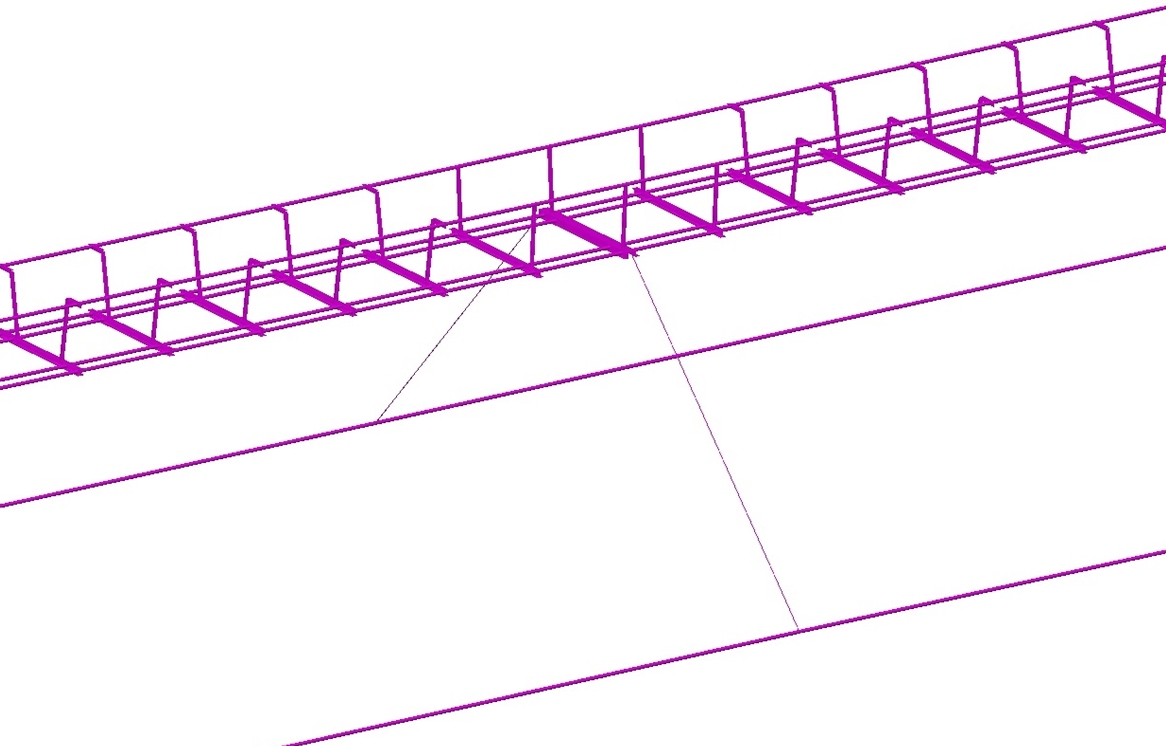

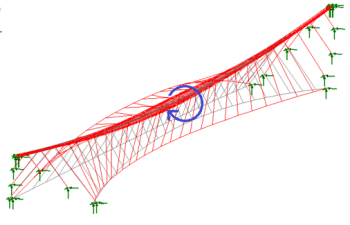

Detail showing

wind cables

|

|

|

|

|

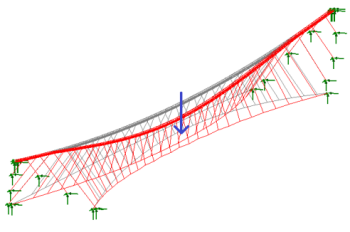

| First

vertical eigenmode

|

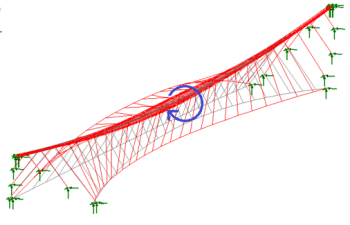

First

torsional eigenmode |

In addition to verifiying the structural elements,

the staged construction process involving the erection of the main cables and

wind

cables was also designed, checked and controlled step-by-step with

LUSAS with the help of the global model and with secondary cable models.

|

|

|

Animation

showing tensioning of the wind cable system (side, end and

plan views) |

The accuracy of the LUSAS analysis was

proven both during the bridge's construction, during which the main stages were monitored by height and/or force

measurements, and also on its completion by carrying out a static and dynamic load test prior to

opening. The calculated and measured results were in very good agreement.

Access to the bridge

is controlled with no more than 300

pedestrians permitted to use the bridge at the same time - this limit being determined by comfort considerations and not by static capacity

reasons.

Peter Gondar, Senior

Engineer at MSc Engineers and Consultants Ltd. said "This was

one of the most challenging projects in the history of our firm

thanks to the numerous engineering problems that the design of such

a unique bridge hides. The entire design process was highly driven

by the calculations, meaning that not only the general structural

safety but also the geometry, the buildability and the final

serviceability of the bridge depended on the accuracy of the cable

forces."

Construction

images

"Thanks to the geometrical

nonlinear and staged construction capabilities of LUSAS we managed

to solve the global structural and construction analysis with high

level of precision and fulfill the client’s expectations in all

respects."

Peter Gondar, Senior

Engineer, MSc Engineers and Consultants Ltd., Hungary

Main participants:

-

Client: Municipality of Sátoraljaújhely

-

Contractor: Graboplan-Industrie Ltd.

-

Bridge designer: MSc Engineers and Consultants Ltd.

Find out more

Other LUSAS Bridge case studies:

|

Case

Study

Case

Study